CONTROL AND CHOKE VALVE MANUFACTURER SINCE 1967

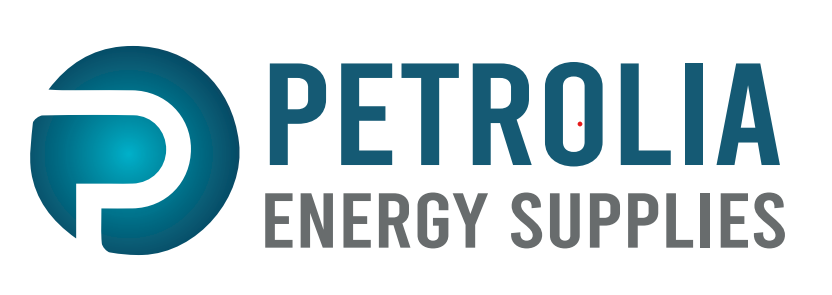

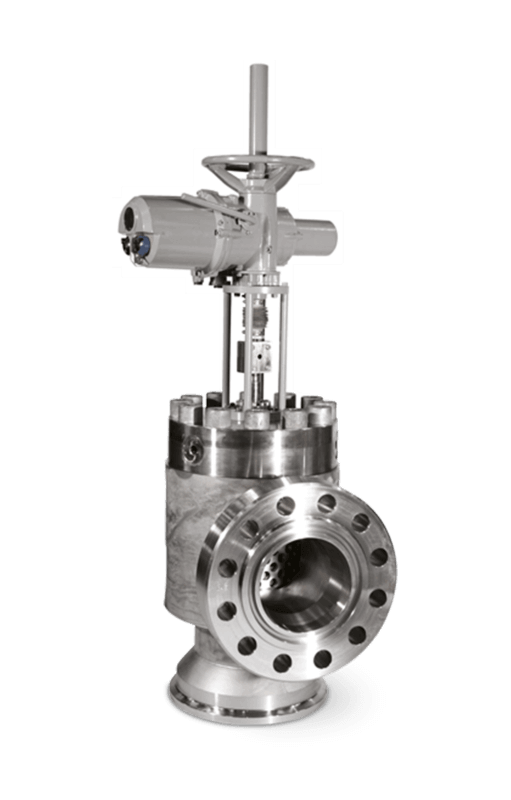

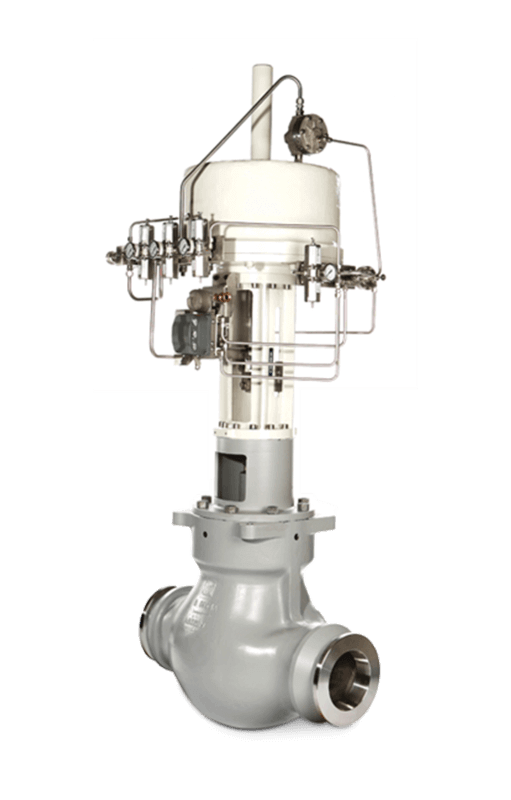

Kentintrol Range of Valves

Kentintrol also provides

PNEUMATIC AND ELECTRO-PNEUMATIC

Our two valve positioners are designed to move actuators, in accordance with a control signal, when used with a control valve. Options include pneumatic and electro-magnetic, both of which are built to withstand rough handling and vibration.

ViewSERIES A VALVE AIRSETS

Our Valve Airsets and Air Filters are designed to work with control valves and actuators. They are lightweight, durable and can operate in even the most hostile service conditions and environments. The Series A Airset range consists of three airsets with different port sizes and flow rates to suit different applications. They share a number of common features and are designed to offer long-life performance even in hostile environments. All are provided with an epoxy-coated bracket and feature a metal bowl, which is easy to remove. ViewSERIES 1000 AND SERIES 3000

Our Series 1000 and Series 3000 Valve Volume Boosters can help improve the stroking speed of an actuator, or increase the flow capacity. They reproduce pneumatic signals in a 1:1 ratio. For maximum performance, when used on diaphragm actuators, the volume booster unit should be installed as close as possible to the actuator. Other features of our volume boosters include:

ViewPA SERIES

Our PA Series valve airlocks are designed to help actuators to work more effectively. They do so by blocking the pressure in the diaphragm chamber of the actuator when the air pressure falls below the desired set value (1.0 – 4.0 kg/cm²). The design of the PA Series features a built-in relief valve which exhausts air from the diaphragm chamber if there is a need to manually operate the actuator. This prevents damage to the diaphragm. The PA Series airlocks form part of our wide range of instruments which also includes actuators, positioners, volume boosters, air filters and airsets.

ViewSERIES G,C & D

Our range of Pneumatic Actuators have been designed to meet the needs of all applications. Typical users include onshore, offshore and power applications. They have been used effectively and reliably for many years in each of these applications. Whilst the specifications vary, they all give you the peace of mind of knowing that they have been professionally designed and manufactured. We use high quality materials, with full traceability through all stages of the manufacturing process.

View