LEADERS IN SEALING INTEGRITY

Garlock is a multinational manufacturer of high-performance fluid sealing and pipeline solutions with an emphasis on safety, longevity, and productivity. We work in partnership with our customers, industry associations, and governmental entities to understand their unique sealing challenges and respond with innovative solutions that keep people safe while increasing profitability.

About Garlock

With a history dating back over 125 years, Garlock today maintains a global presence of manufacturing and distribution facilities that allow it to meet their customers’ needs with unprecedented responsiveness and ingenuity.

Garlock also operate state-of-the-art research, development, and testing facilities that continue to advance the state of the sealing industry to meet the rapidly changing demands of our industrial customers.

By combining the most innovative products with unparalleled service and a strong environmental commitment, Garlock deliver solutions that improve plant productivity, reduce costs, and comply with increasingly stringent environmental regulations.

A Culture of Excellence, Guided by Safety

Quite simply, safety is what we do. Our sealing solutions protect millions of people everyday from exposure to life-threatening materials. Durability, ease of maintenance and other benefits are essential to the value of using a Garlock sealing solution, but without safety, none of those other factors would matter.

In addition to designing and manufacturing safety-focused sealing solutions, we also offer a wide range of safety-oriented training for our customers. As a division of EnPro Industries — named one of the safest U.S. companies by EHS Today — Garlock is able to provide its customers with access to the EnPro Learning System. The EnPro Learning System offers consulting services, safety courses, and safety conferences throughout the year to help other companies and professionals implement safety excellence at their facilities.

This commitment to safety also extends to our own facilities. Garlock is heavily invested in creating a safe workplace and empowering our employees to take ownership and responsibility for the safety of themselves and their co-workers. Our exemplary safety record contributes significantly to EnPro’s frequent recognition as one of the nation’s safest companies.

Garlock Range of Products

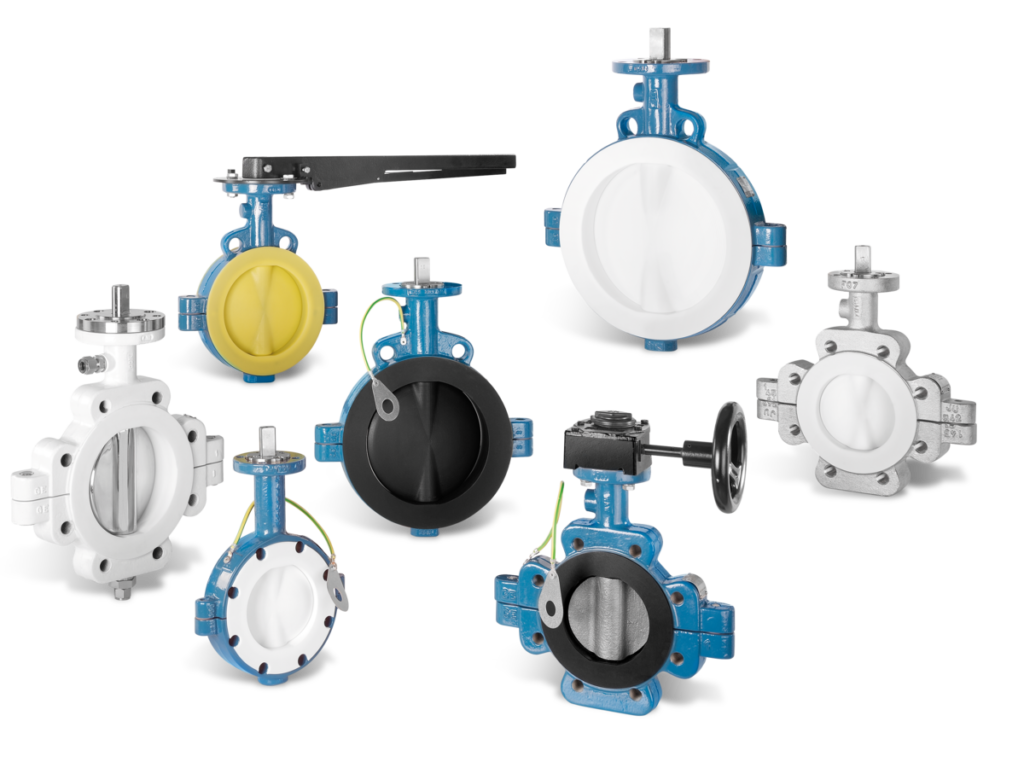

Butterfly Valves are renowned throughout the chemical, petrochemical, Garlock process, and many other industrial sectors for their quality, performance and reliability in demanding conditions. Garlock valves set the standard in TA-Luft compliance, plus the valves are certified with SIL 3 according to EN 61508.

GAR-SEAL® Butterfly Valves

Used where corrosive, abrasive, and toxic media need to be reliably controlled

MOBILE-SEAL® Butterfly Valves

Used on road tanker vehicles, railway cars, silos, and other transportation and storage containers.

SAFETY-SEAL® Butterfly Valves

Used where electrostatic charges must be avoided.

STERILE-SEAL® Butterfly Valves

Valves for Sterile Processes

Valve Accessories

Handles, special locking handles, gear operators, air actuators, limit switches, and electro-pneumatic positioners.

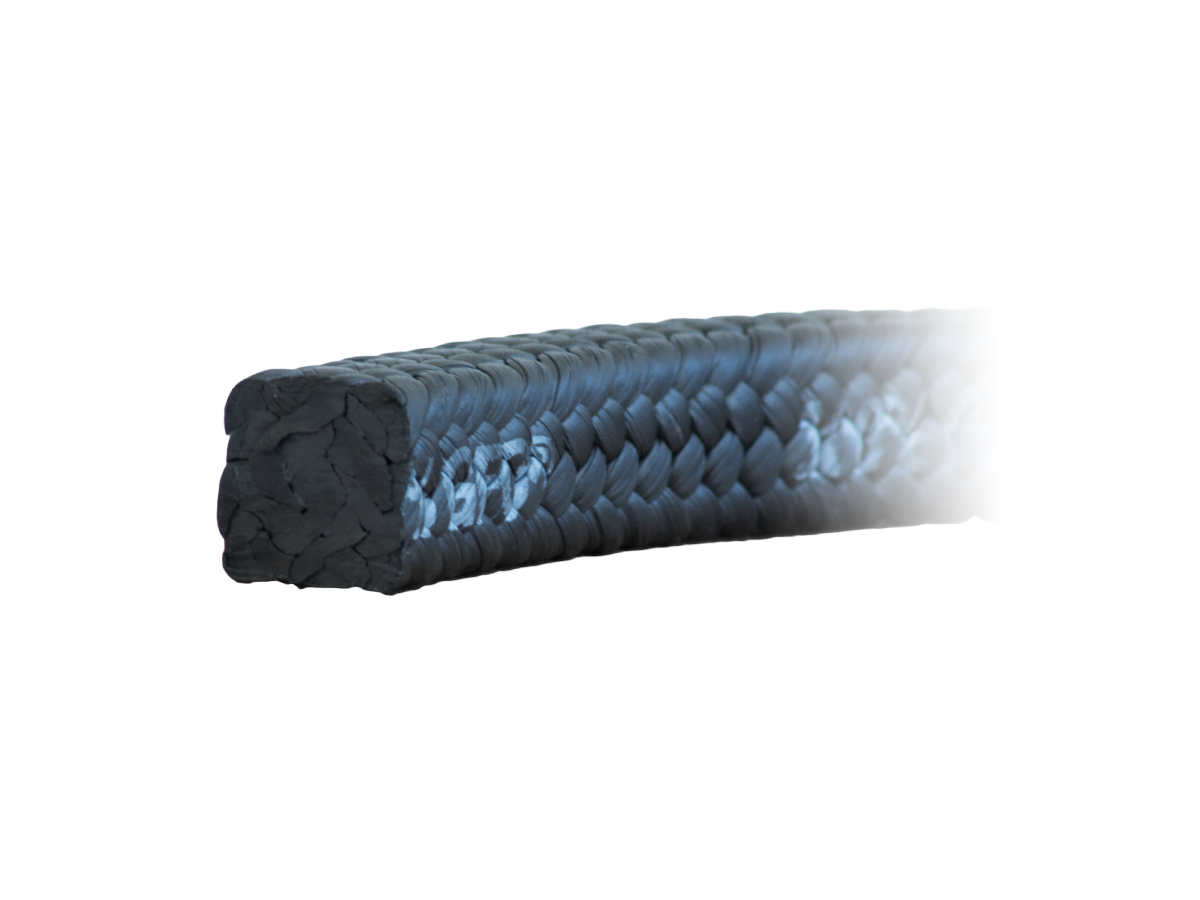

Garlock Compression Packing will contribute to maintain a safe process, meet stringent fugitive emission limits and save resources, with proven reliability.

Garlock compression packing is rigorously tested to ensure effective sealing in valves, pumps, agitators, and other rotary equipment. The development of the compression packing line reflects the evolution and innovation in the materials used in its production. Garlock develops and manufactures it’s own technical yarn braided into packing, along with high performance proprietary coatings, that are essential in this age of sealing performance requirements.

Garlock’s product line includes industry recognized Low Emission valve stem packing, leading-edge and award winning pump packing sets like dry-running DSA, and water saving HYDRA-JUST®. We pioneered the development of emission control valve stem packing in the early 1980s. Our innovation efforts have yielded a portfolio of low emission packing products to suit customer needs and meet EPA’s latest requirements.

Carbon Packing

Garlock Premium Carbon Packing offer field proven performance, versatility and longevity.

Graphite Packing

For high speed and high temperature applications

Valve Stem Packing

Safe, reliable, and long-lasting valve packing solutions

Pump/Rotary Equipment Packing

Garlock offers a full range of field proven pump packing systems designed to be reliable and cost-effective.

Soot Blower Packing: Tornado Pack

Garlock Soot Blower Sets offer exceptional safety, reliability, and performance

PTFE Packing

General service ePTFE packing for pump and mixer applications.

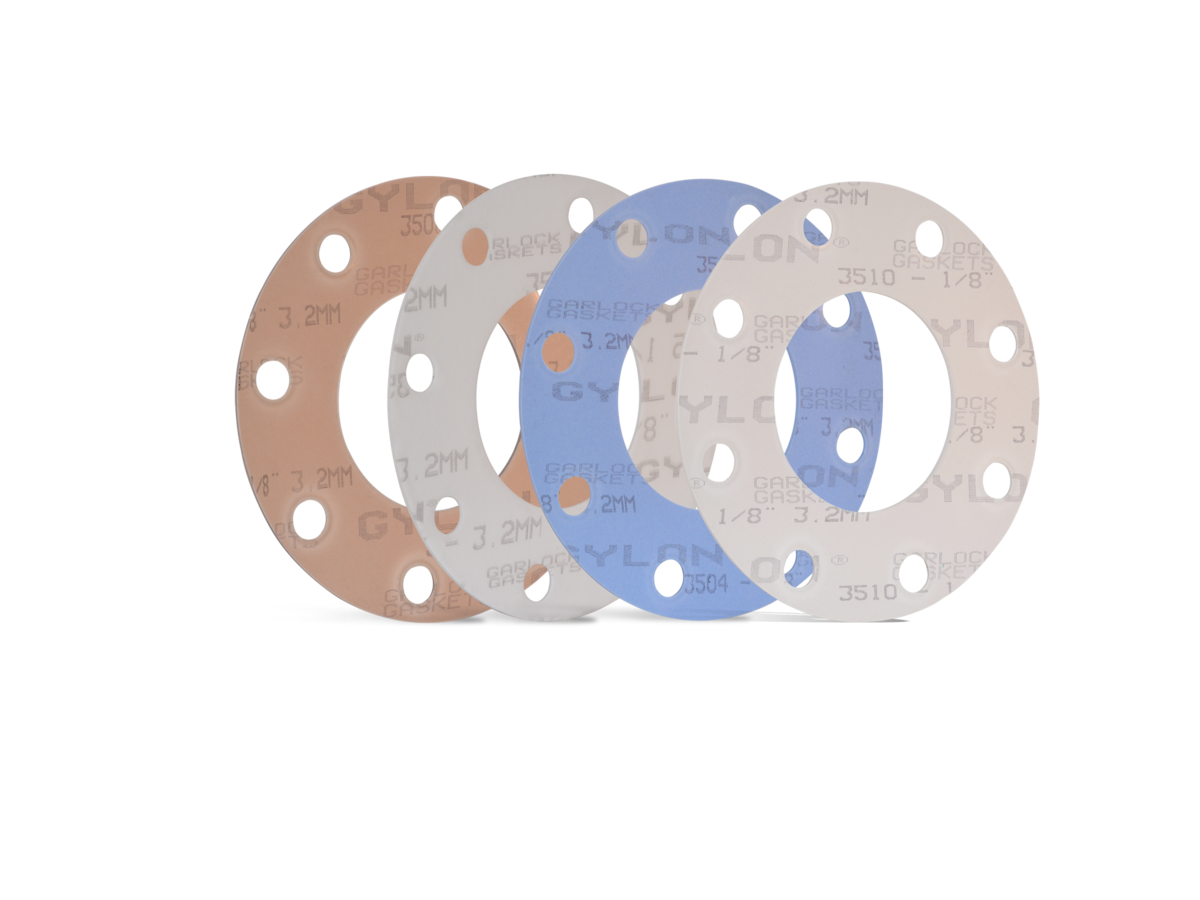

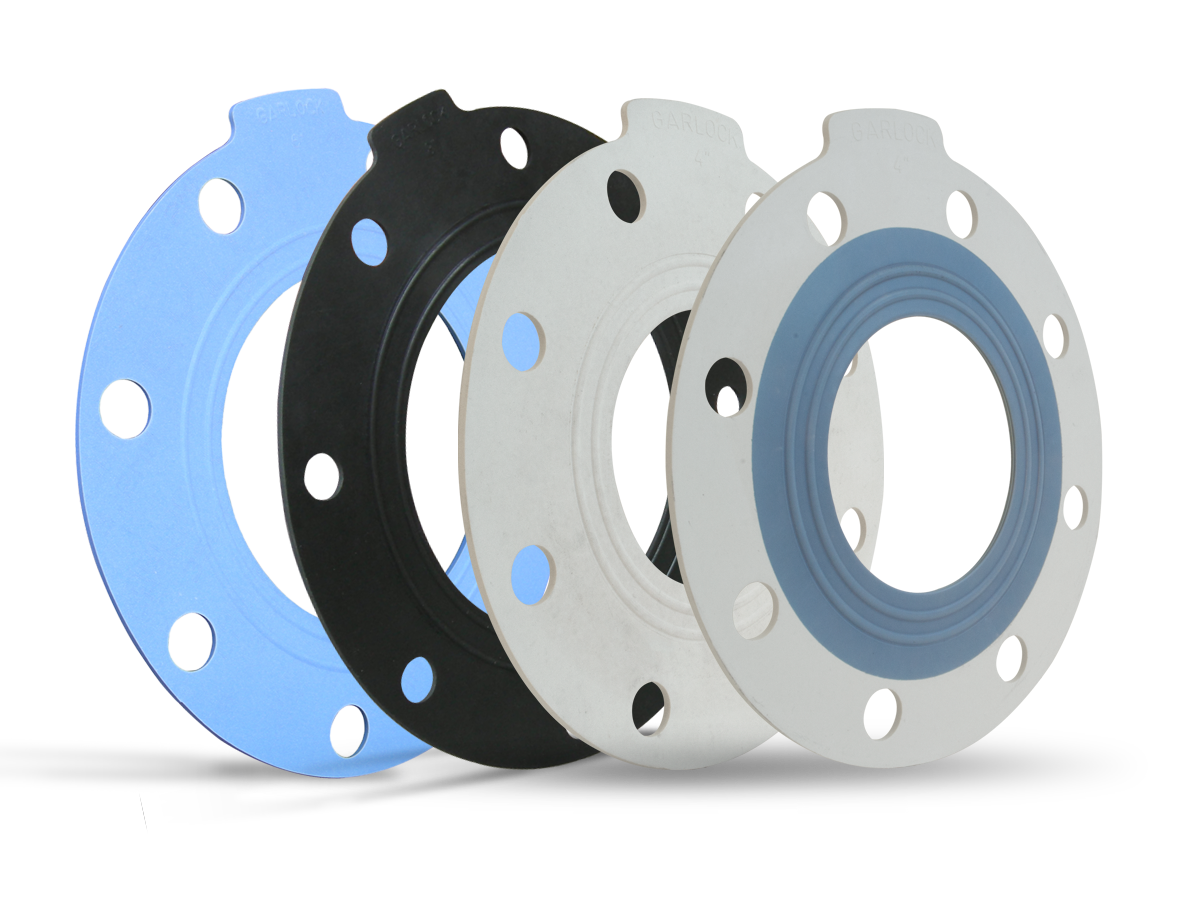

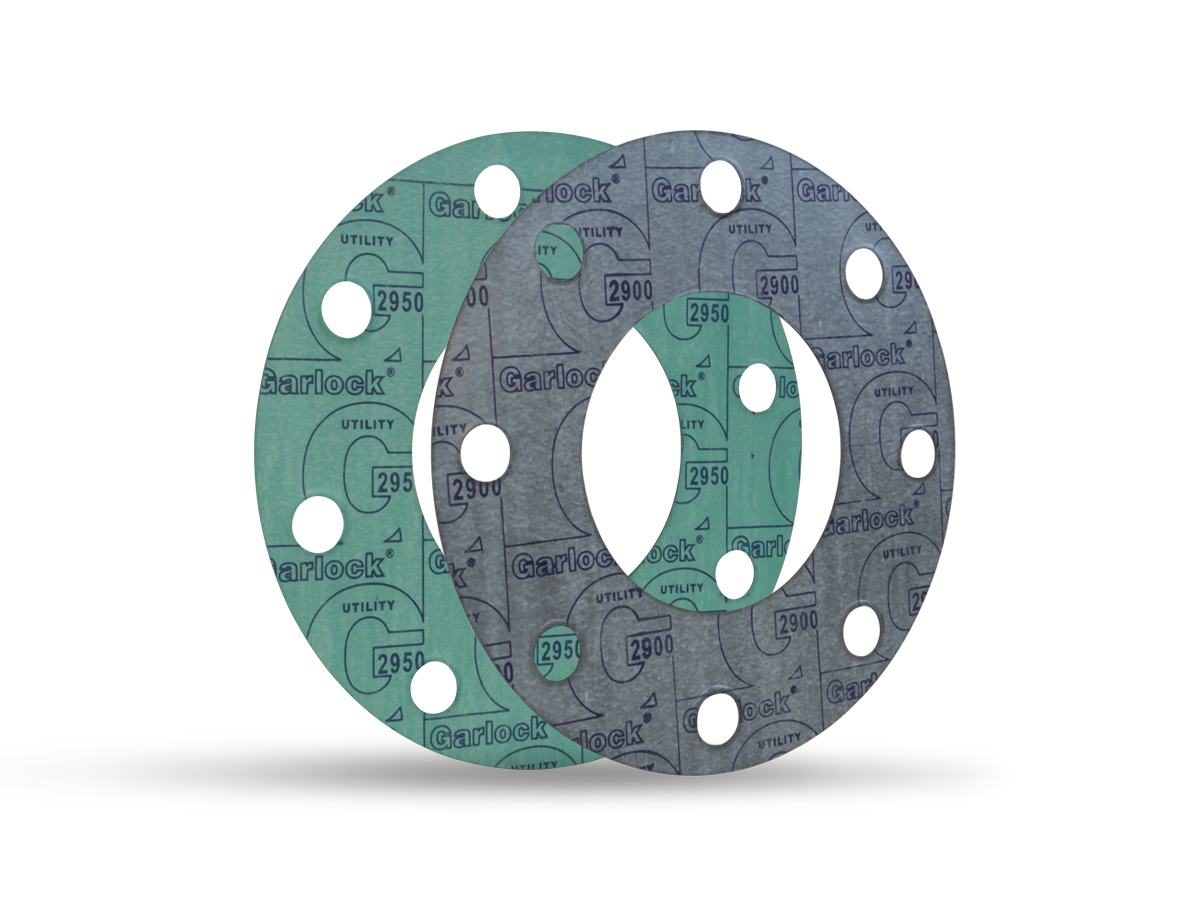

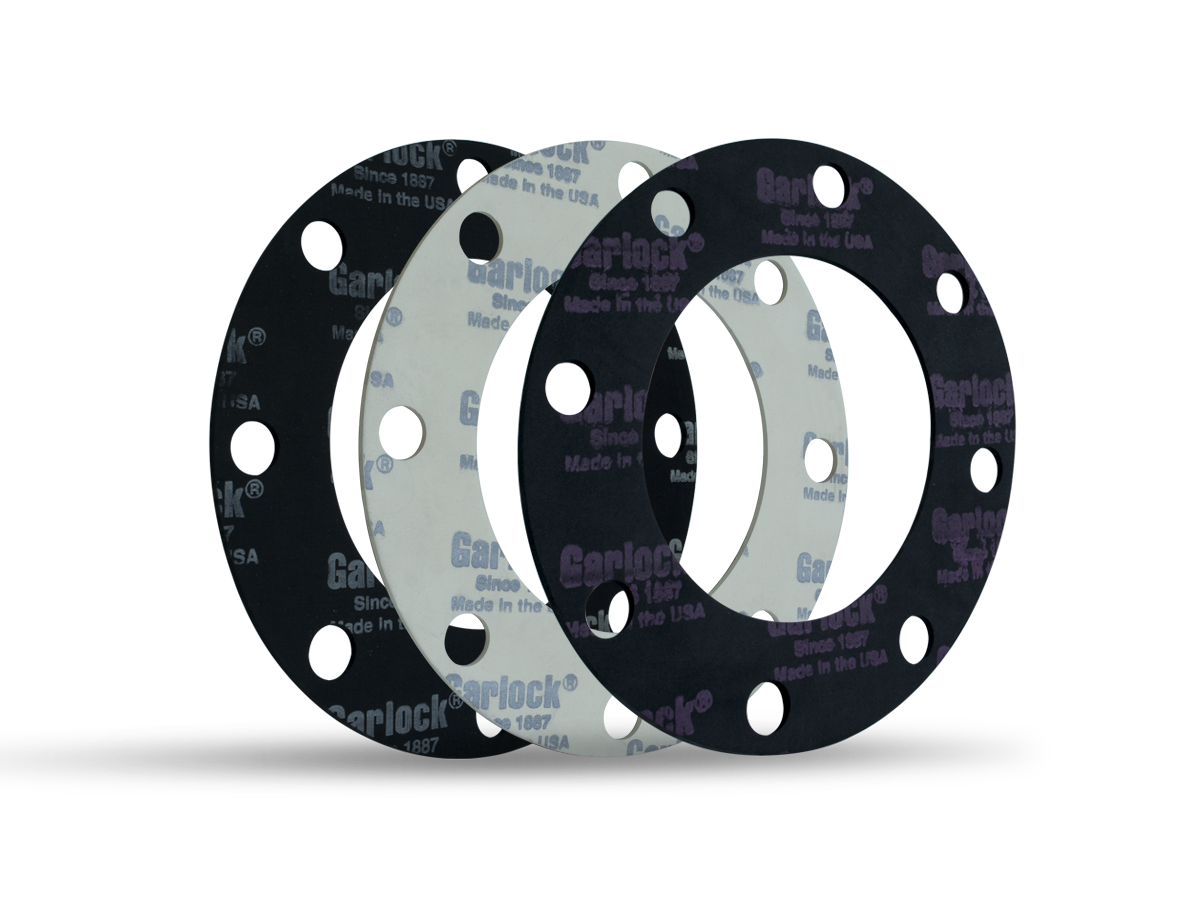

Garlock® gasketing is offered in a wide range of materials, including GYLON® restructured PTFE, compressed fiber gasketing, GRAPH-LOCK® flexible graphite sheet, THERMa-PUR Extreme Temperature gasketing and high performance rubber sheet products.

GYLON® is a time-tested proven product that is known throughout industry as the material of choice for severe chemical services. In addition, GYLON® gasket size availability is virtually limitless, as the product can be thermally bonded using a patented process.

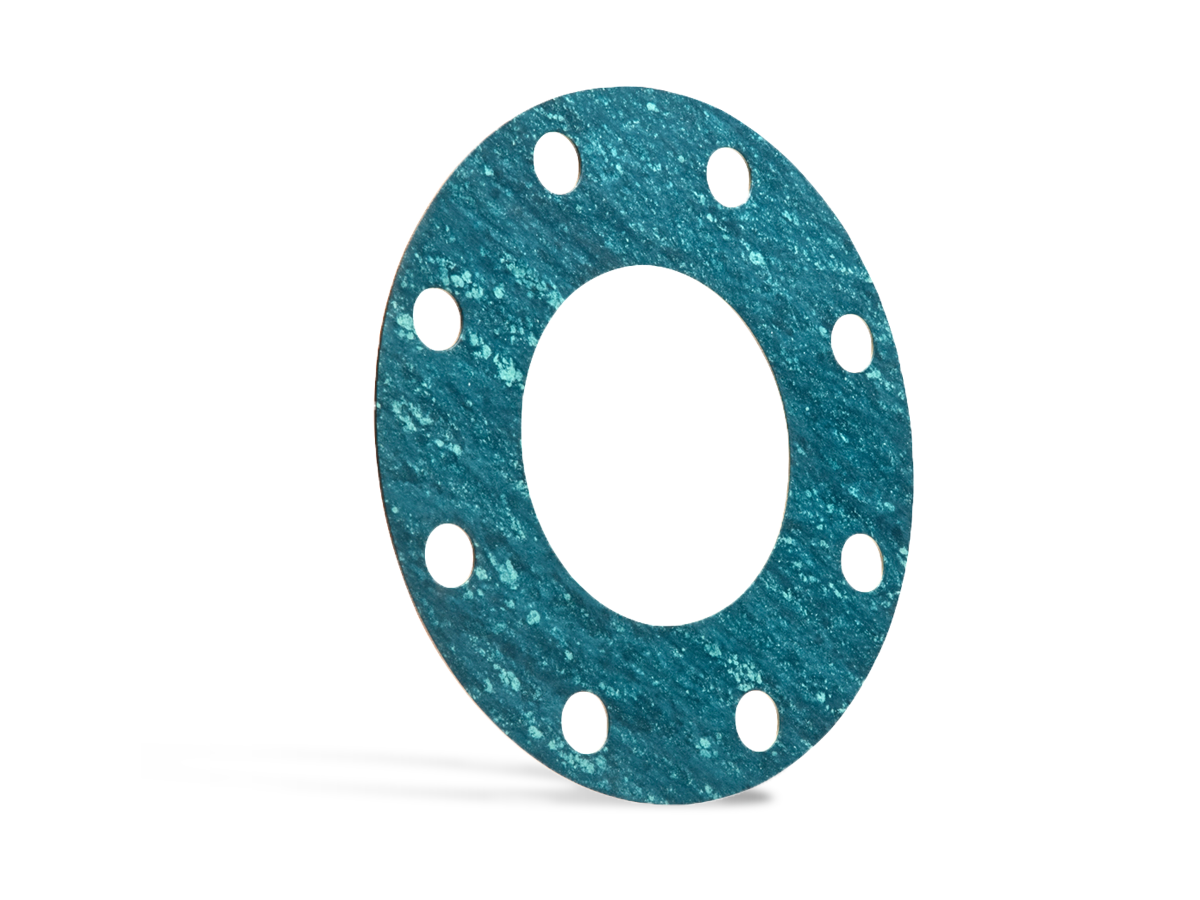

Garlock’s compressed fiber gasketing materials are manufactured using a proven technique referred to as the High Pressure Sheet (HPS) process. One thing that makes the Garlock product different from other HPS products is the way they are made using a proprietary non-VOC solvent which is environmentally friendly.

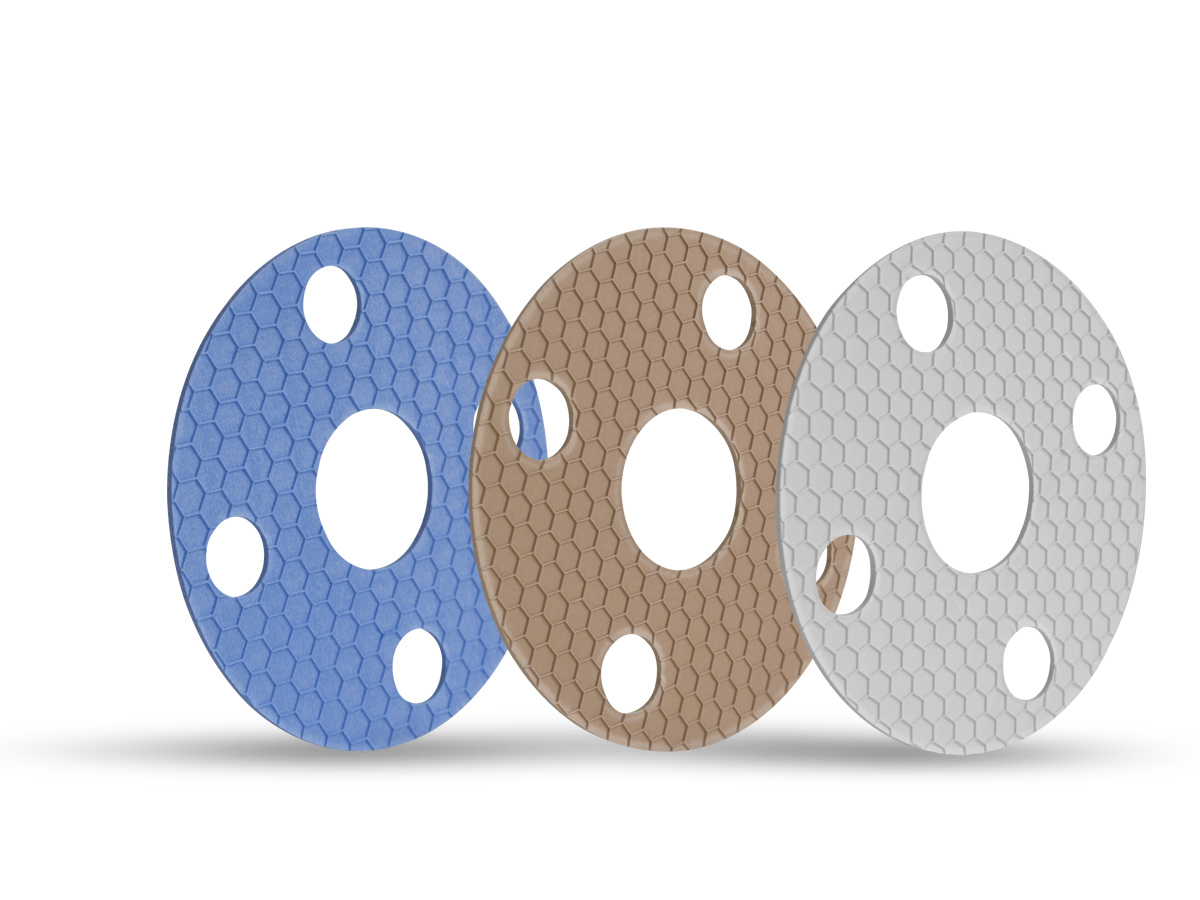

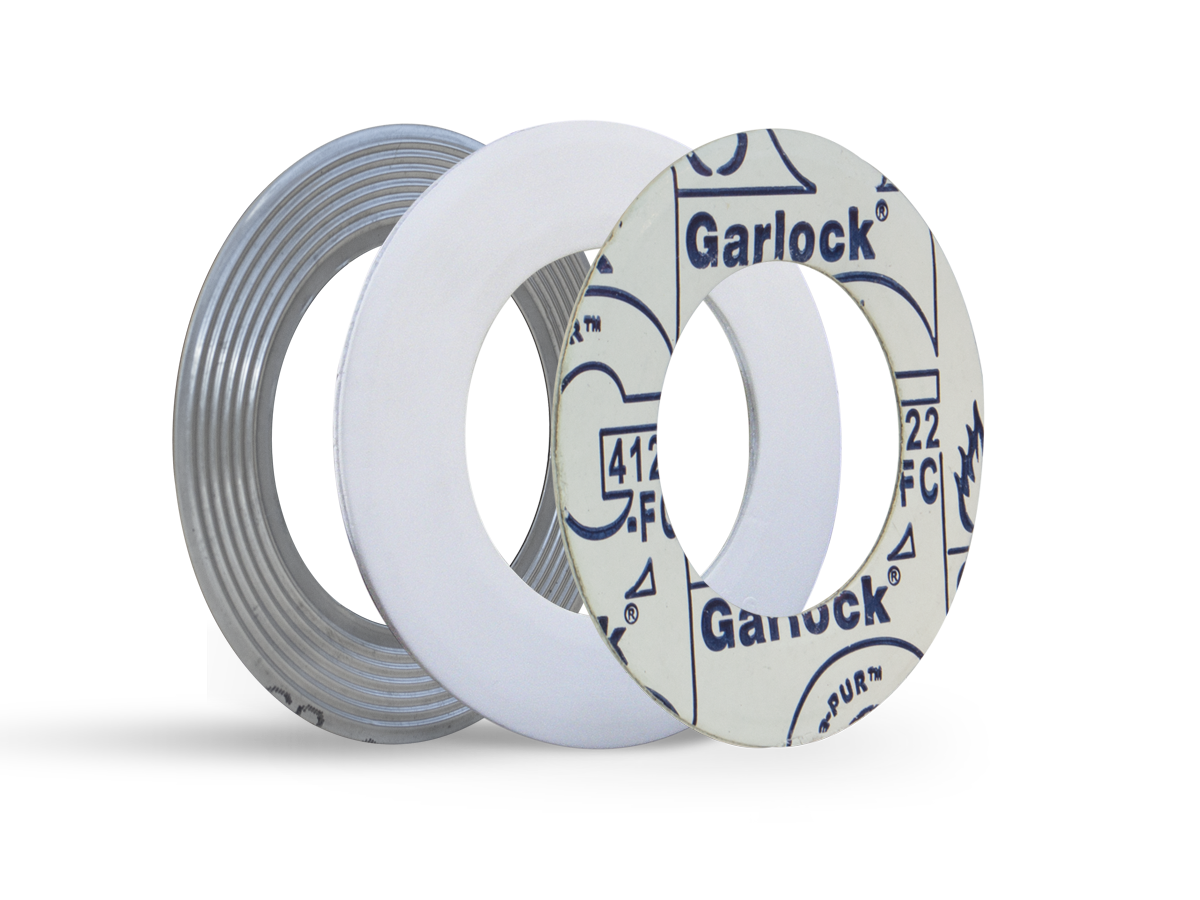

GYLON EPIX® Gaskets

GYLON EPIX® is a newly developed family of PTFE gaskets – patented, profiled surface for optimum sealing performance.

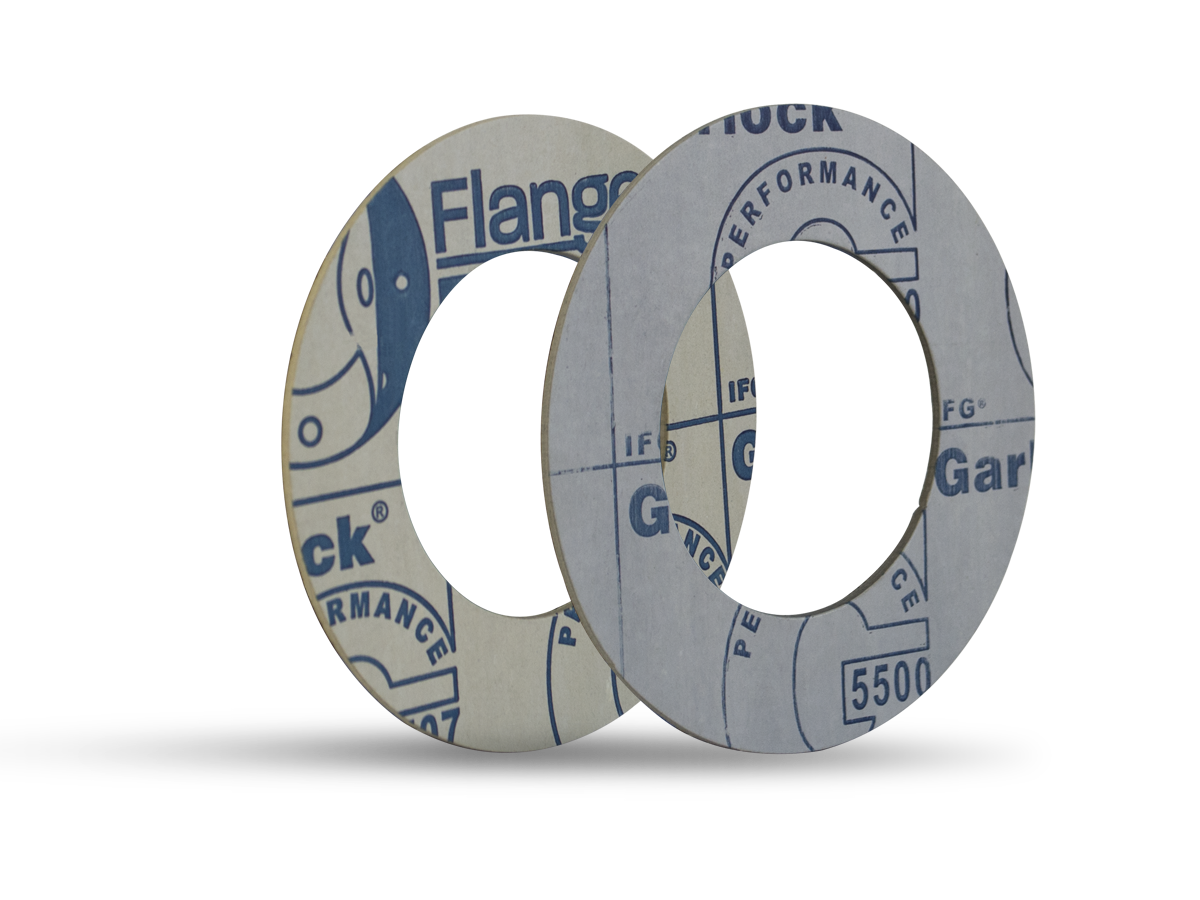

GYLON® Gasketing

Severe service PTFE gasketing

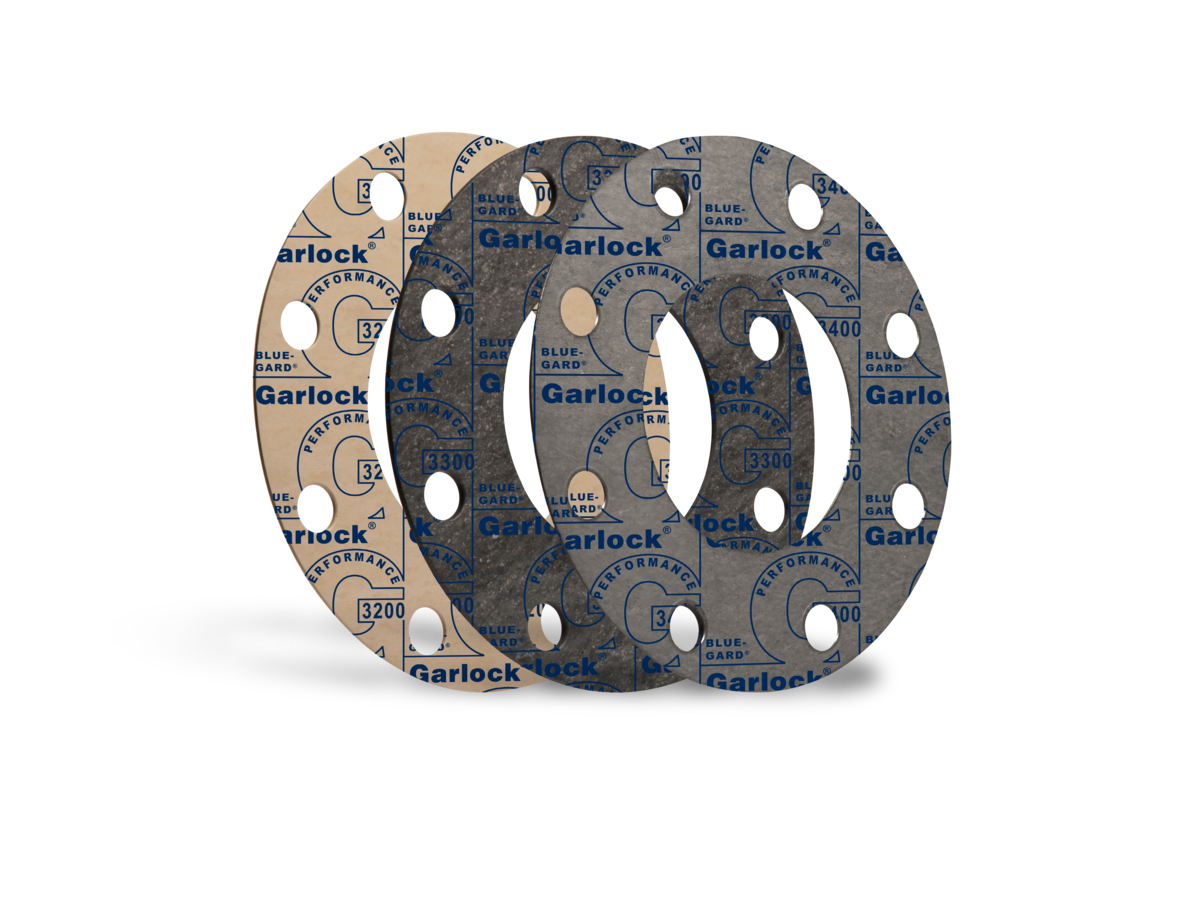

BLUE-GARD®

Compressed Gasketing

STRESS SAVER® Gaskets

The Garlock® STRESS SAVER® family of products feature molded, raised ribs that help to create a tighter seal by concentrating the compressive load…

TUFF-RAIL® Manway Gaskets

The GYLON® TUFF-RAIL® Family consists of two tank car manway gaskets.

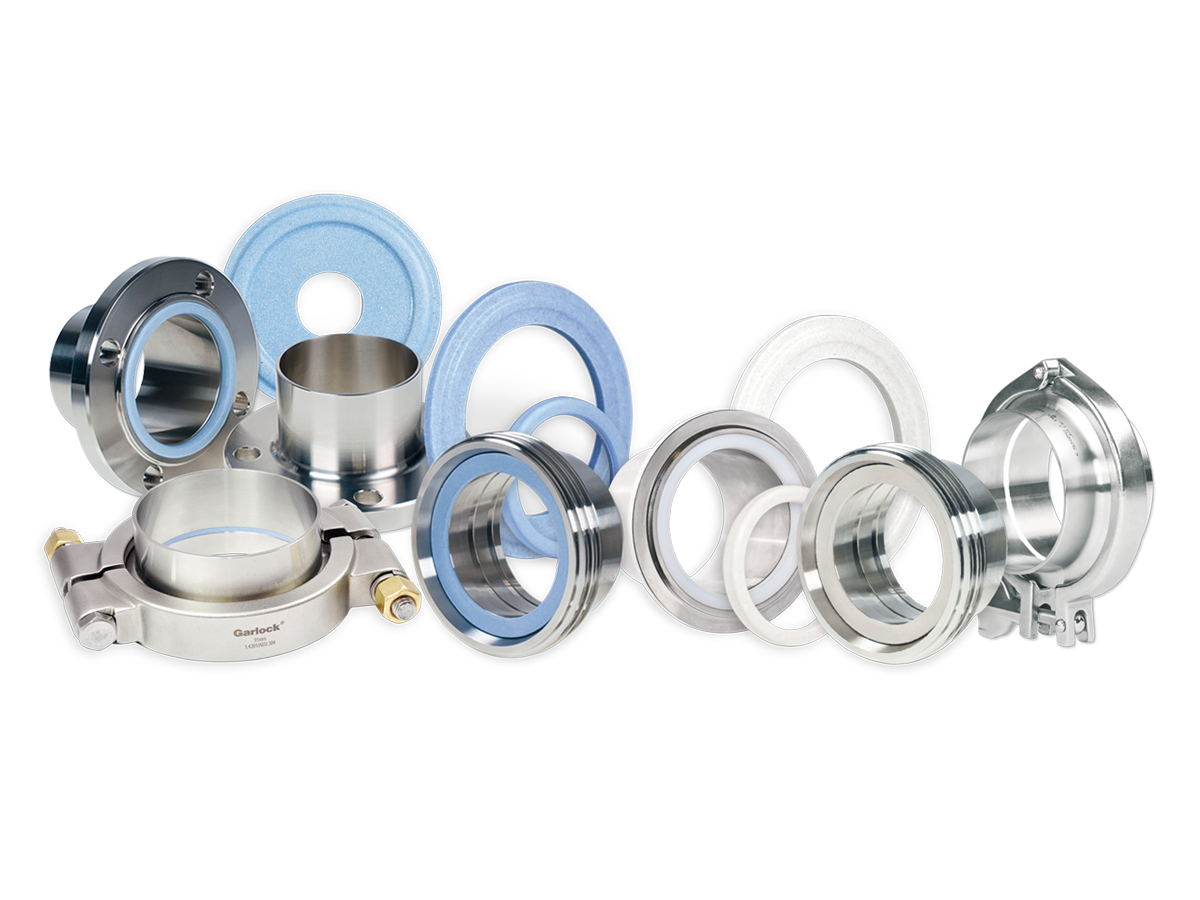

GYLON BIO-LINE® Aseptic Food Grade PTFE Gaskets

Process and equipment reliability for all pharmaceutical and food processing applications

MULTI-SWELL™ Controlled Swell Sheet Gasketing

The only true “controlled swell sheet” available on the market today.

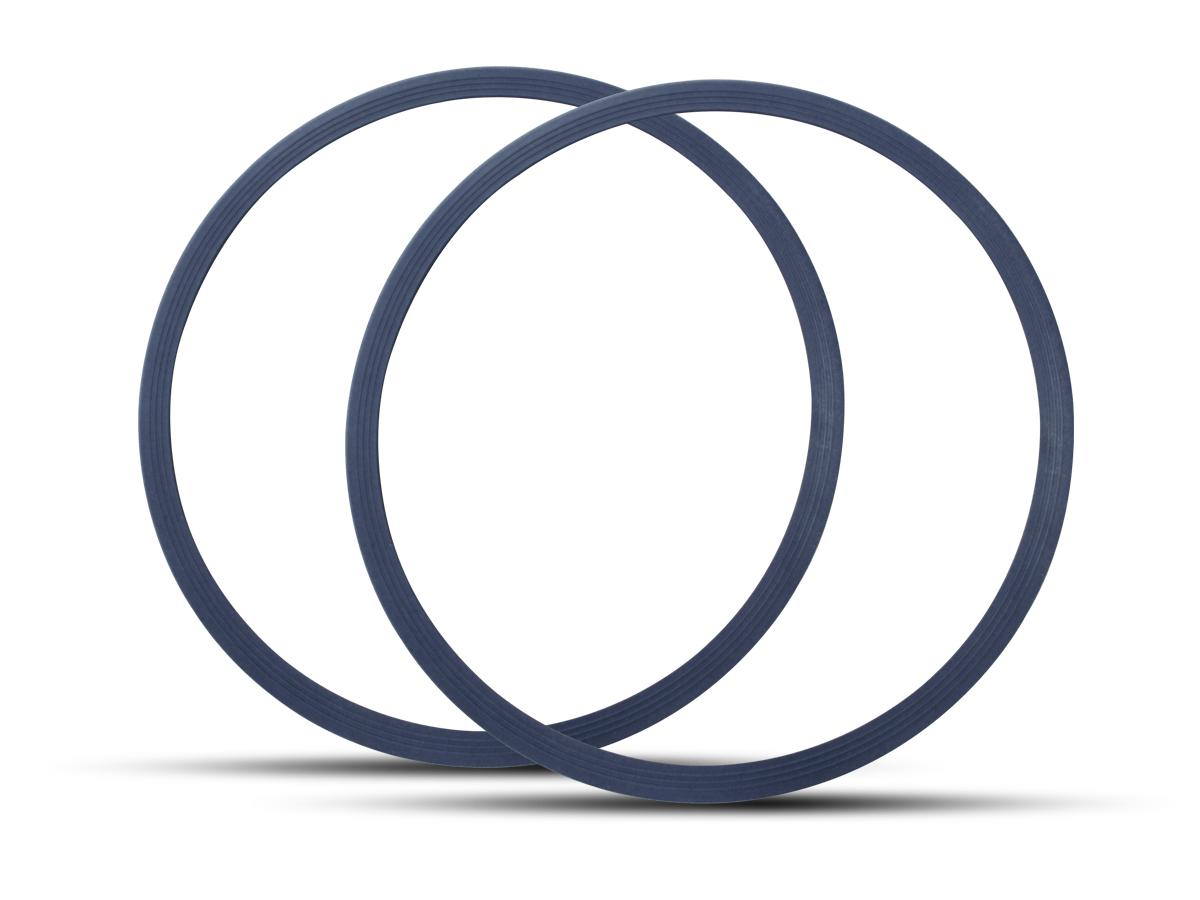

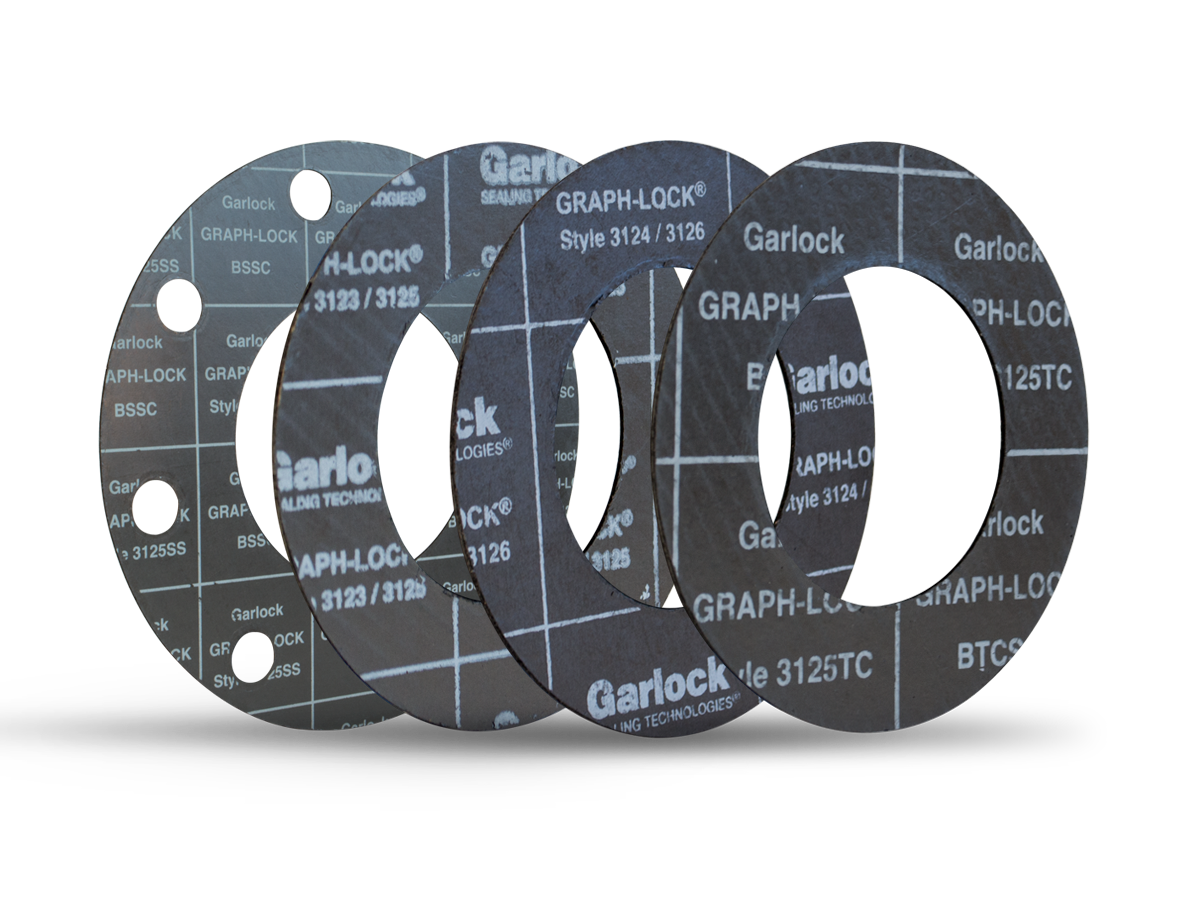

GRAPH-LOCK® Flexible Graphite Gasketing

Withstands high temperatures, high pressures, and aggressive chemicals. Proven fire safe

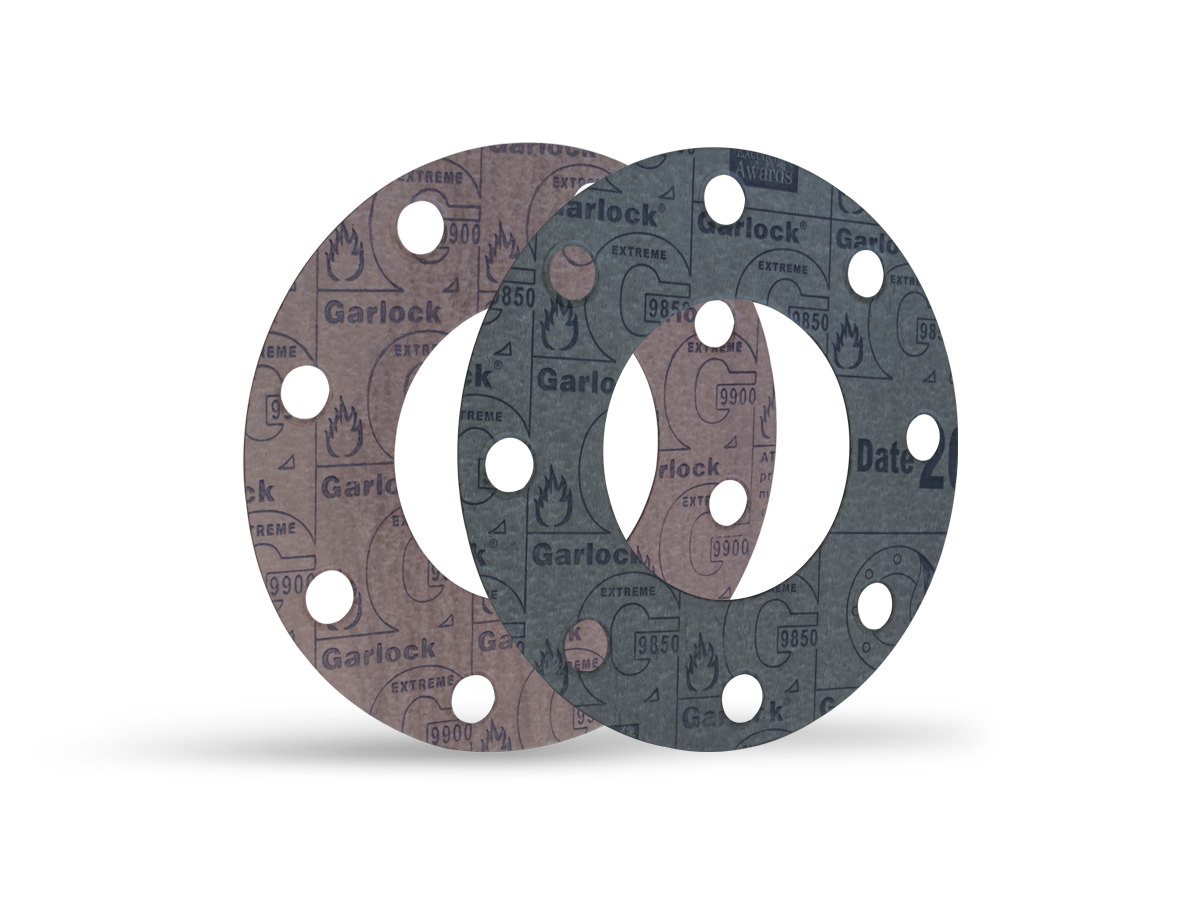

High Temperature Gaskets

Excels in the harshest conditions—intense heat, high pressure, saturated steam and hot oils. Laboratory tested for fire safety. Cut and sheet…

Inorganic Fiber Gasketing

Excellent thermal stability,oxidation resistance, reduced creep relaxation and improved torque retention

Vegetable Fiber Gasketing

Low cost gaskets that utilize vegetable fiber for low pressure, low temperature applications.

Utility-Grade Gasketing

Excellent sealability, thermal stability for utility and general service applications. Compressed non-asbestos (CNA) fiber sheet

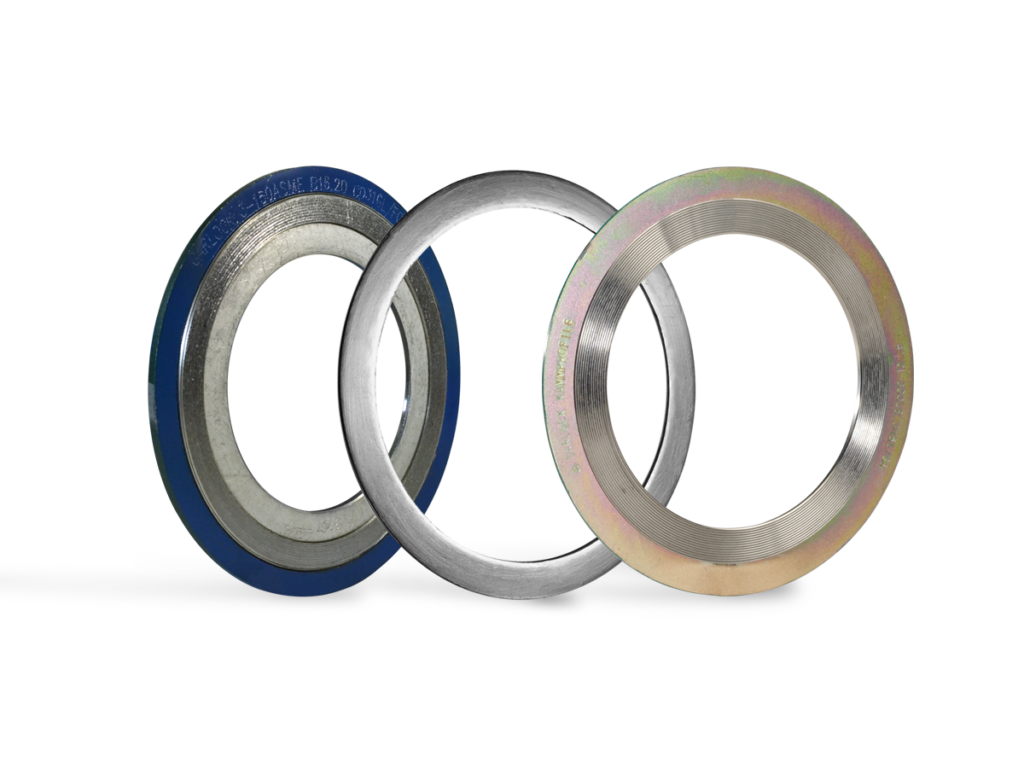

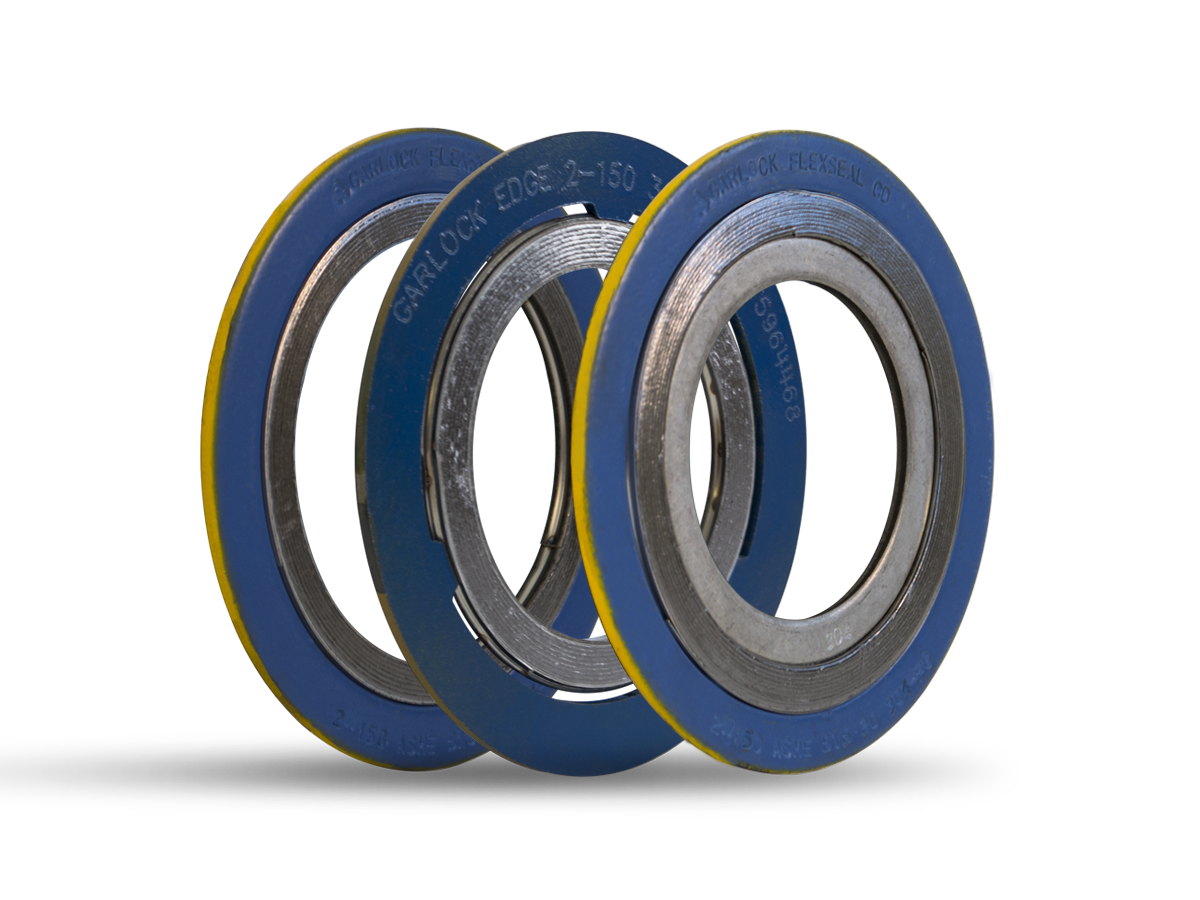

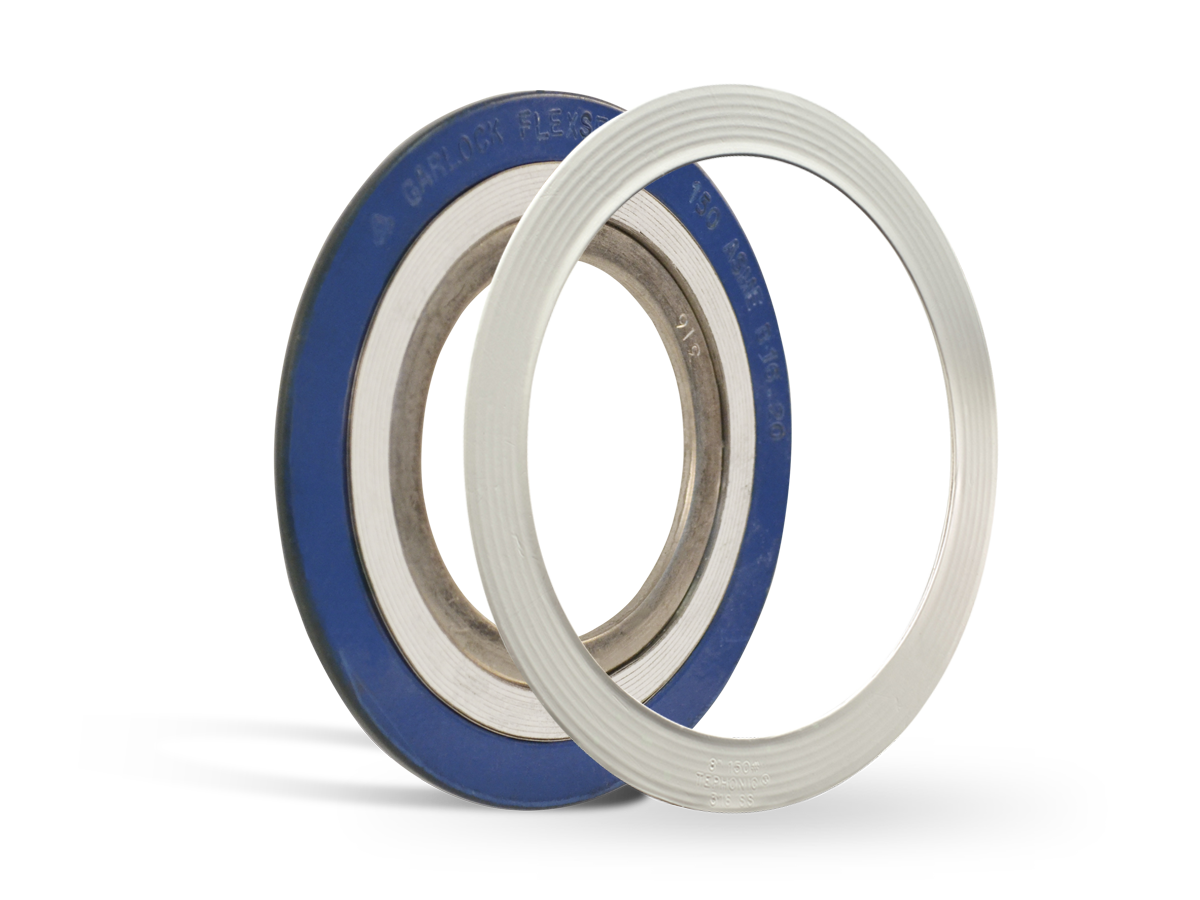

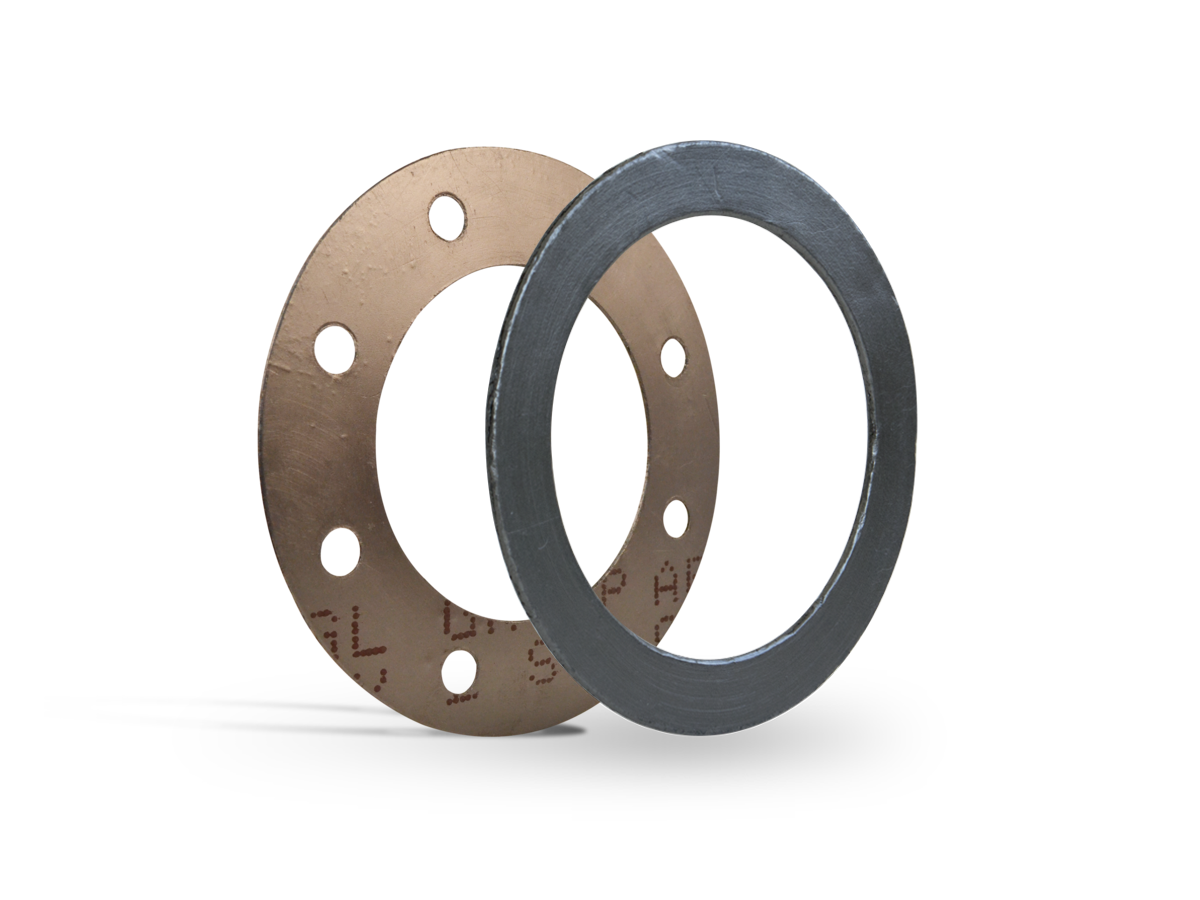

Metal gaskets are designed to withstand extreme temperatures, pressures and chemical exposure. Available in standard and custom configurations, these rugged metal gaskets are made of a wide range of materials to accommodate all types of process applications.

Looking for a product to procure for your construction project? Working on a piping system engineering spec? Need specification help on this product for your system? Our Engineering and Construction team is available for assistance no matter where you are located.

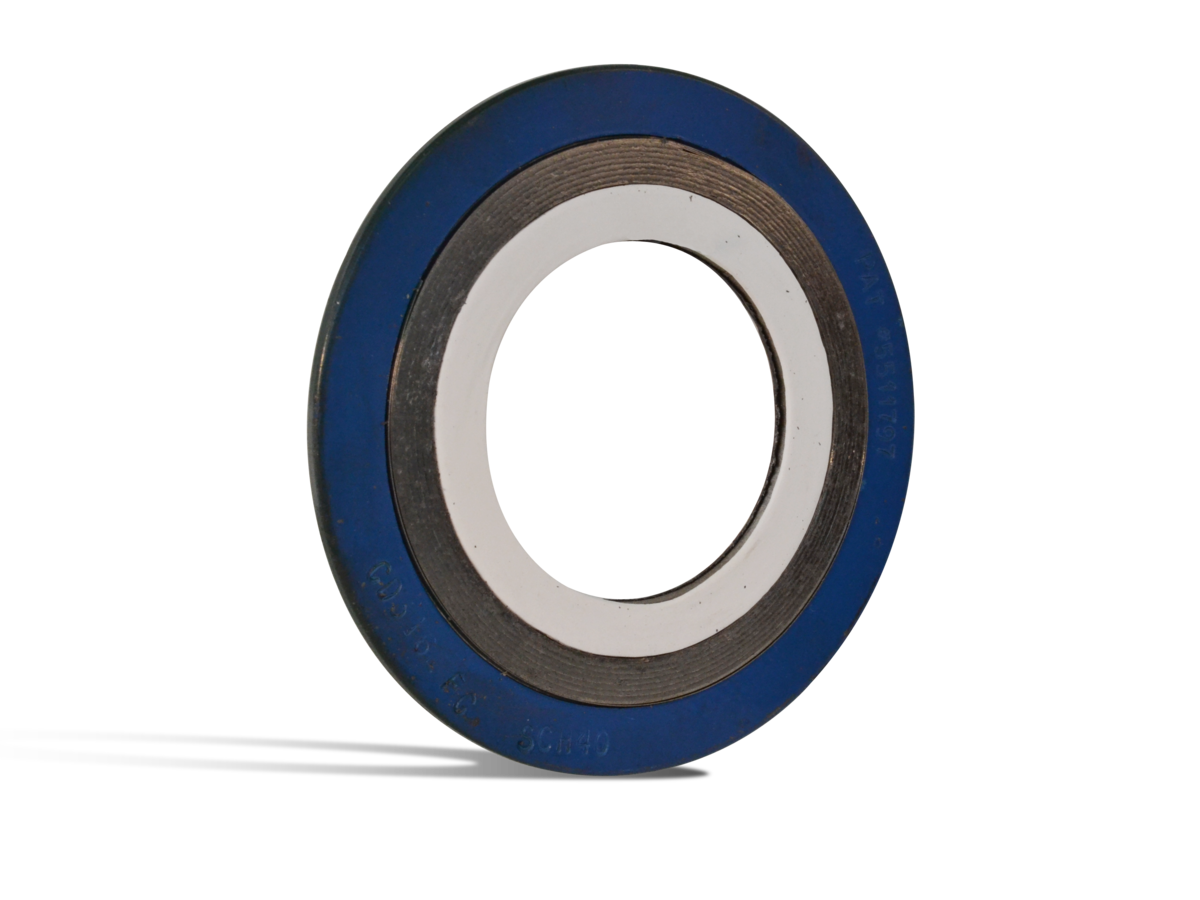

FLEXSEAL® Spiral Wound Gaskets

Garlockʼs FLEXSEAL® spiral wound gaskets provide superior performance and consistent compressibility

Metallic Gaskets featuring THERMa-PUR®

Garlock® THERMa-PUR® gasket material is designed to withstand continuous or cycling temperatures up to 1832°F / 1,000°C.

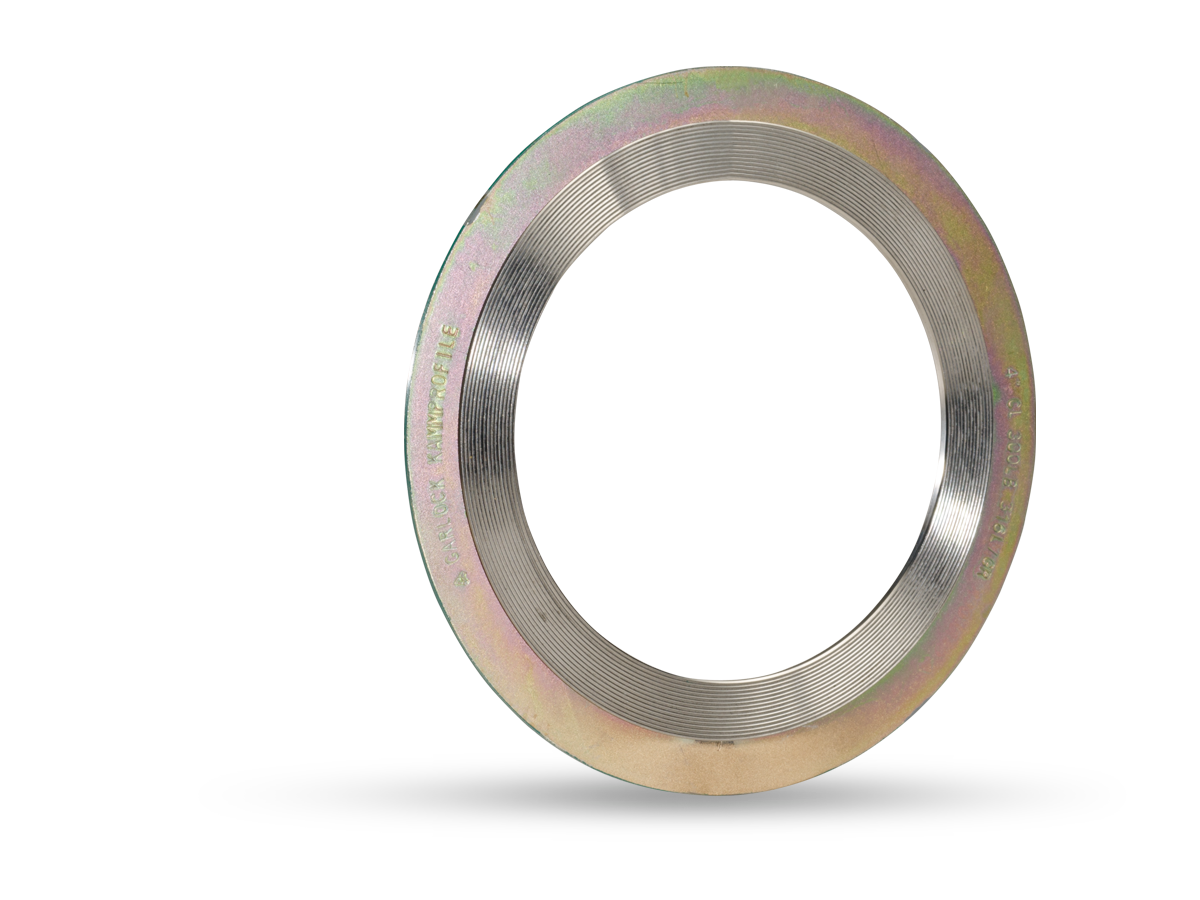

Kammprofile Gaskets

Exceptional reliability in difficult applications

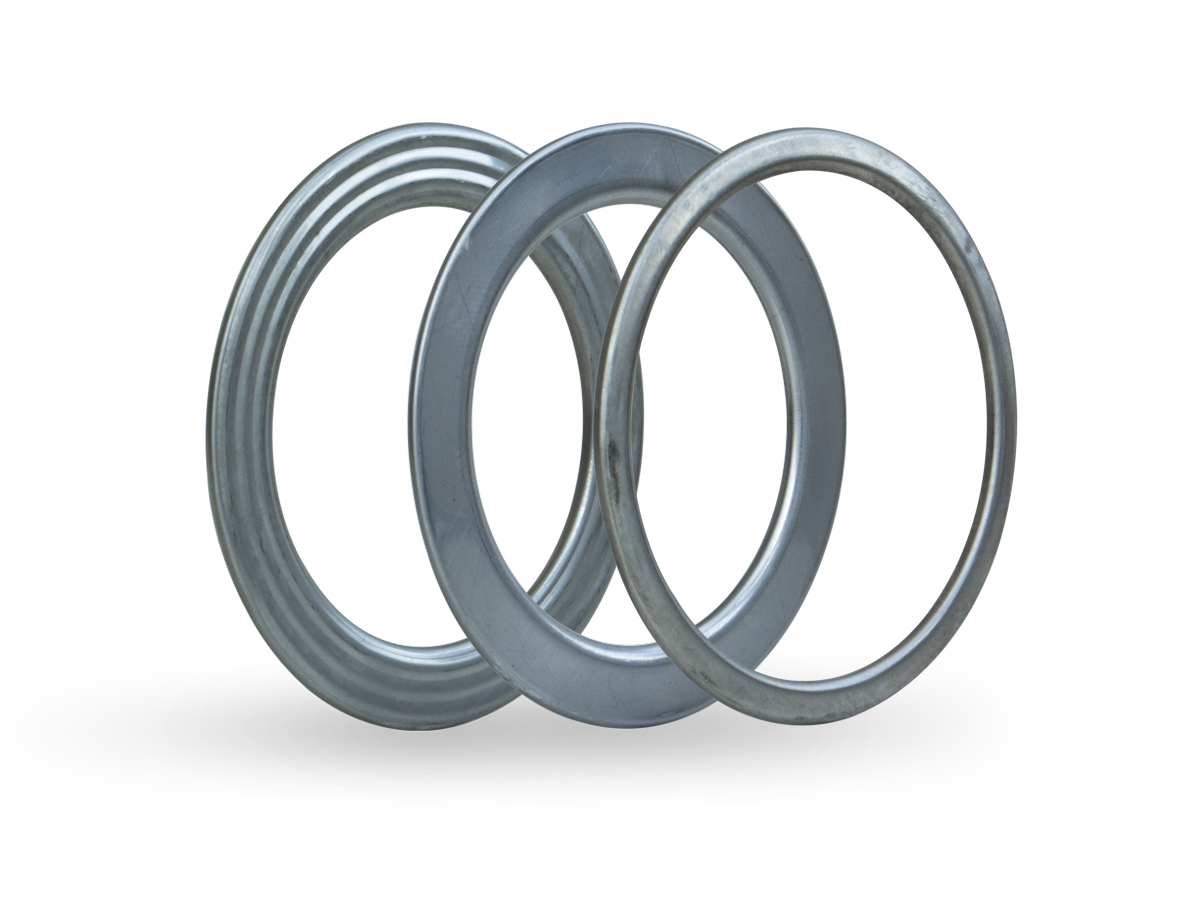

Corrugated Metal Gaskets (CMG)

Corrugated metal core available with four different facing options

FLEXSEAL® TANDEM SEAL™ Gaskets

Patented dual sealing surface designed to reduce corrosion and contamination

Jacketed Gaskets

Jacketed gaskets combine the superior temperature resistance of a metal jacket with the sealing performance of a filler material.

Solid Gaskets

Available with or without facing material

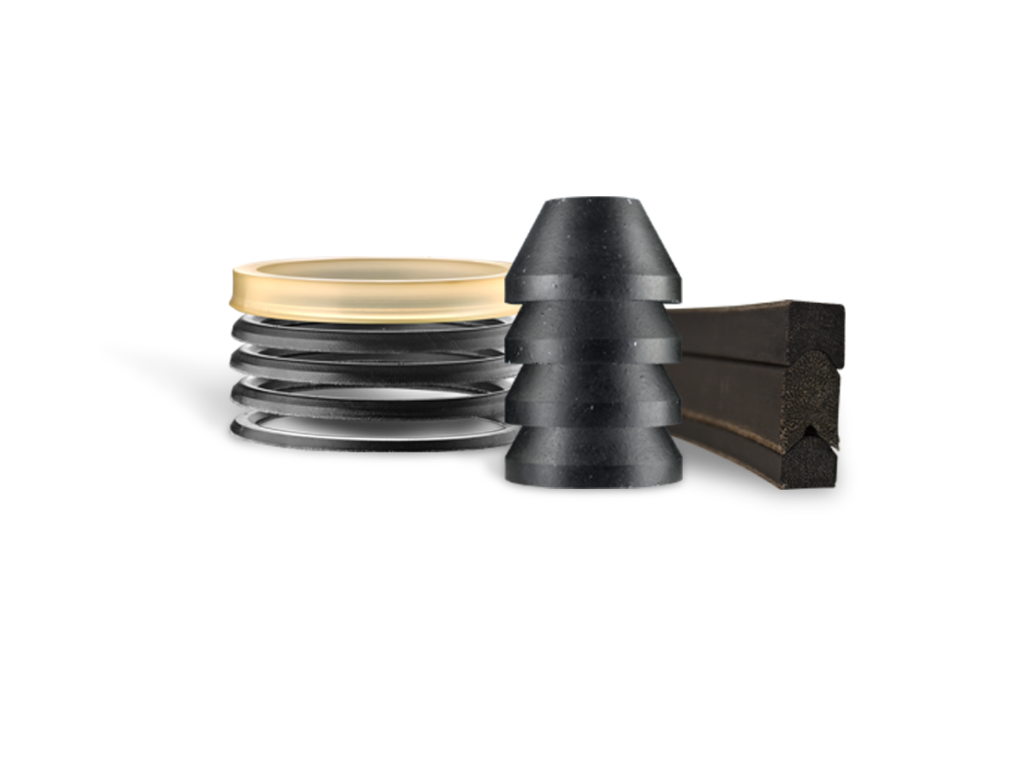

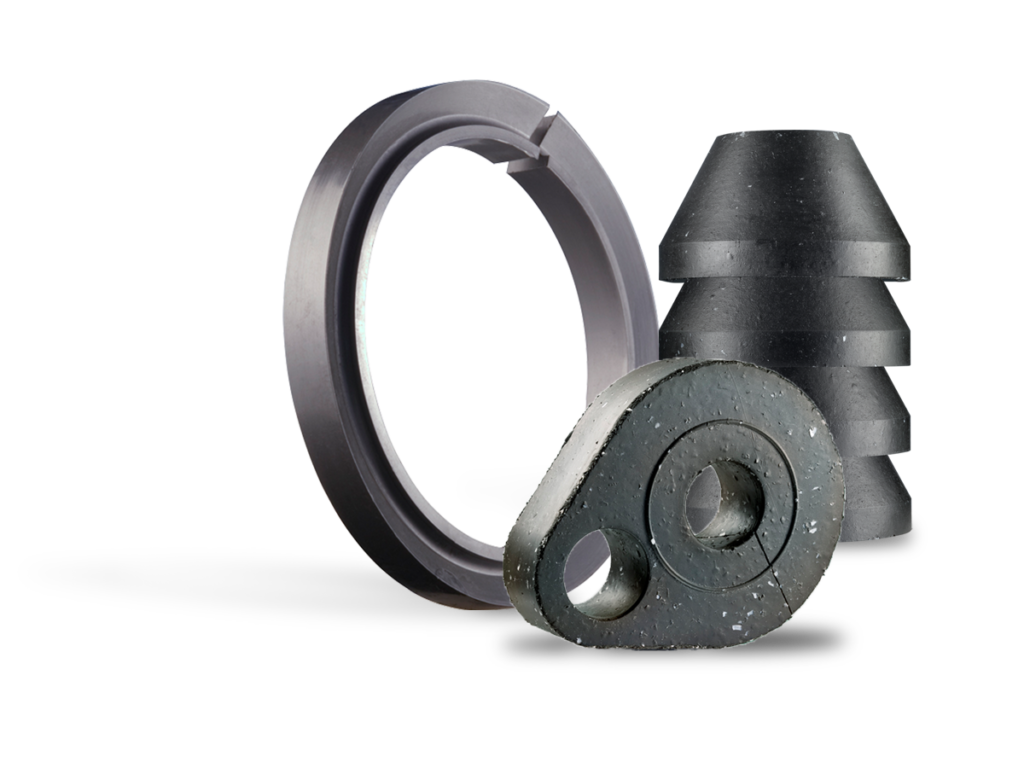

Garlock® hydraulic components include heavy-duty packing and seals to meet the demanding requirements of today’s reciprocating equipment. Key hydraulic component products include CHEVRON® V-ring packing and GARTHANE® urethane seals.

SLUDGE-PAK® Packing

Designed to reduce the friction and abrasion often associated with vertical sludge pumps.

Turbine Blade Runner Packing

Back-to-back packing set specially designed for the Turbine Blade Runner application.

CHEVRON® V-ring Packing

Packing for cylinders, presses, pumps, valves, pistons, and homogenizers.

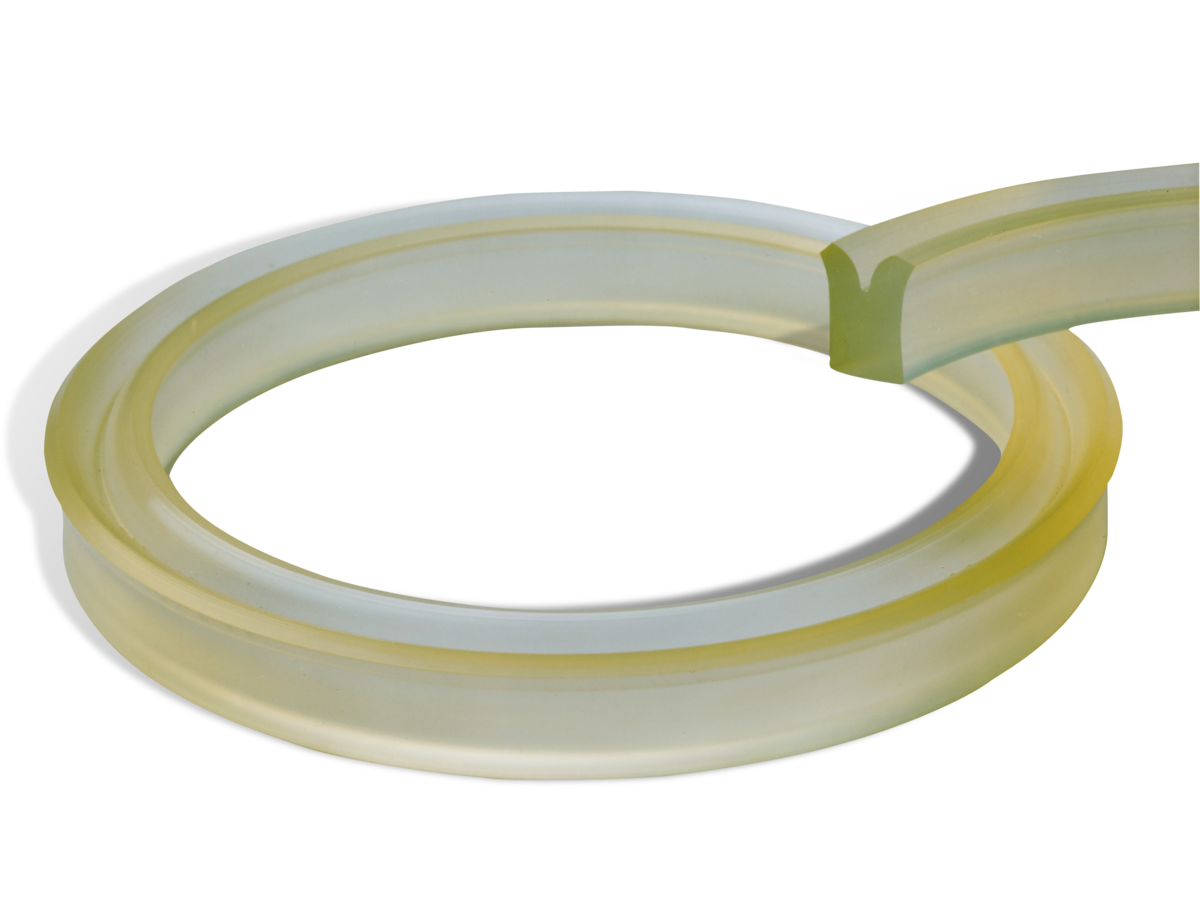

GARTHANE® Urethane Seals

Increased seal life and performance, less equipment downtime, and fewer sizes, saving inventory expenses.

Polytop Sets

Combined CHEVRON® and GARTHANE® sets for exceptional performance.

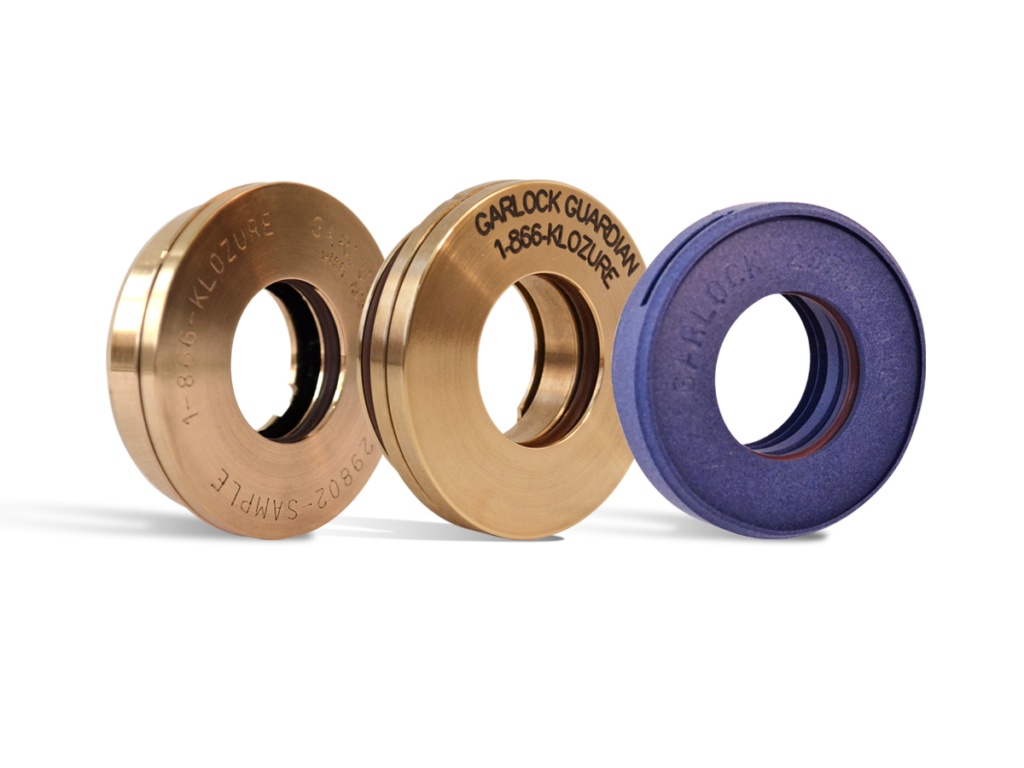

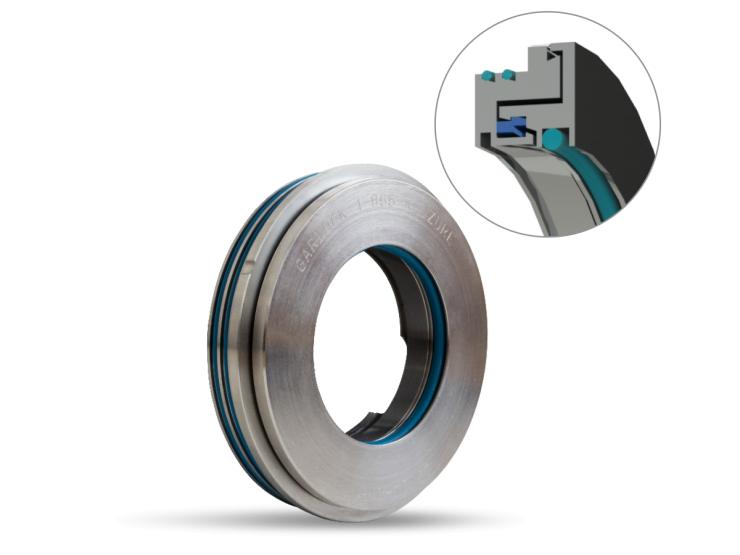

KLOZURE® Bearing Isolators feature a unitized labyrinth design to prevent ingress of contaminants and egress of lubrication. KLOZURE® Bearing Isolators are most commonly found in pumps, motors, and gearboxes. Both split and solid styles are available. All KLOZURE® Bearing Isolators are proudly MADE IN THE USA!

FLOOD-GARD®

FLOOD-GARD® bearing isolators offer the ultimate sealing solution for aggressive, flooded lubrication environments.

GUARDIAN™

Eliminates the metal-to-metal contact between rotor and stator that causes vibration and misalignment which causes traditional O-rings to shred…

MICRO-TEC® II Bearing Isolators

Guardian™ features, but with microcellular foam air filter to capture airborne contamination

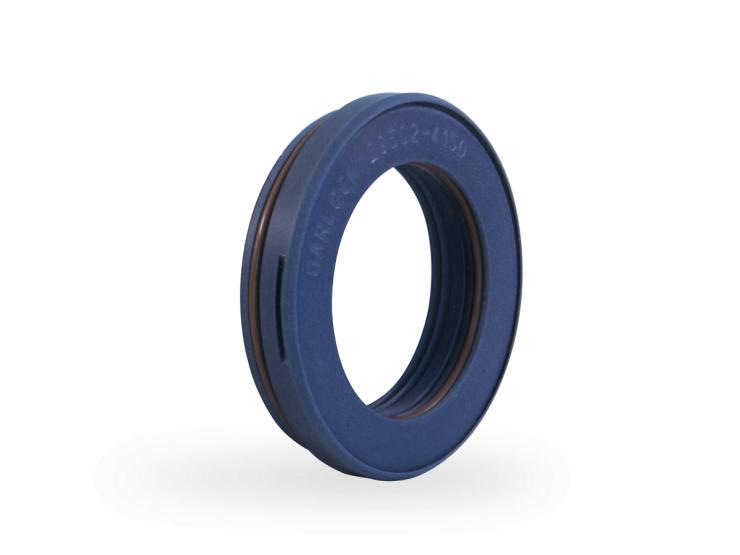

PUR-GARD™ Bearing Isolators

PUR-GARD™ bearing isolators – for the food and beverage processing industry. Manufactured with materials that are FDA compliant.

SGi® Bearing Isolators

Shaft Grounded for VFD Controlled Electric Motors

Split GUARDIAN® Isolators

The first truly unitized split isolator, the Split GUARDIAN™ offers exceptional bearing protection for pumps and motors under the harshest…

ISO-GARD® Bearing Isolators

Bearing protection for pumps, motors, and bearing supported equipment. Filled with PTFE material for excellent chemical resistance

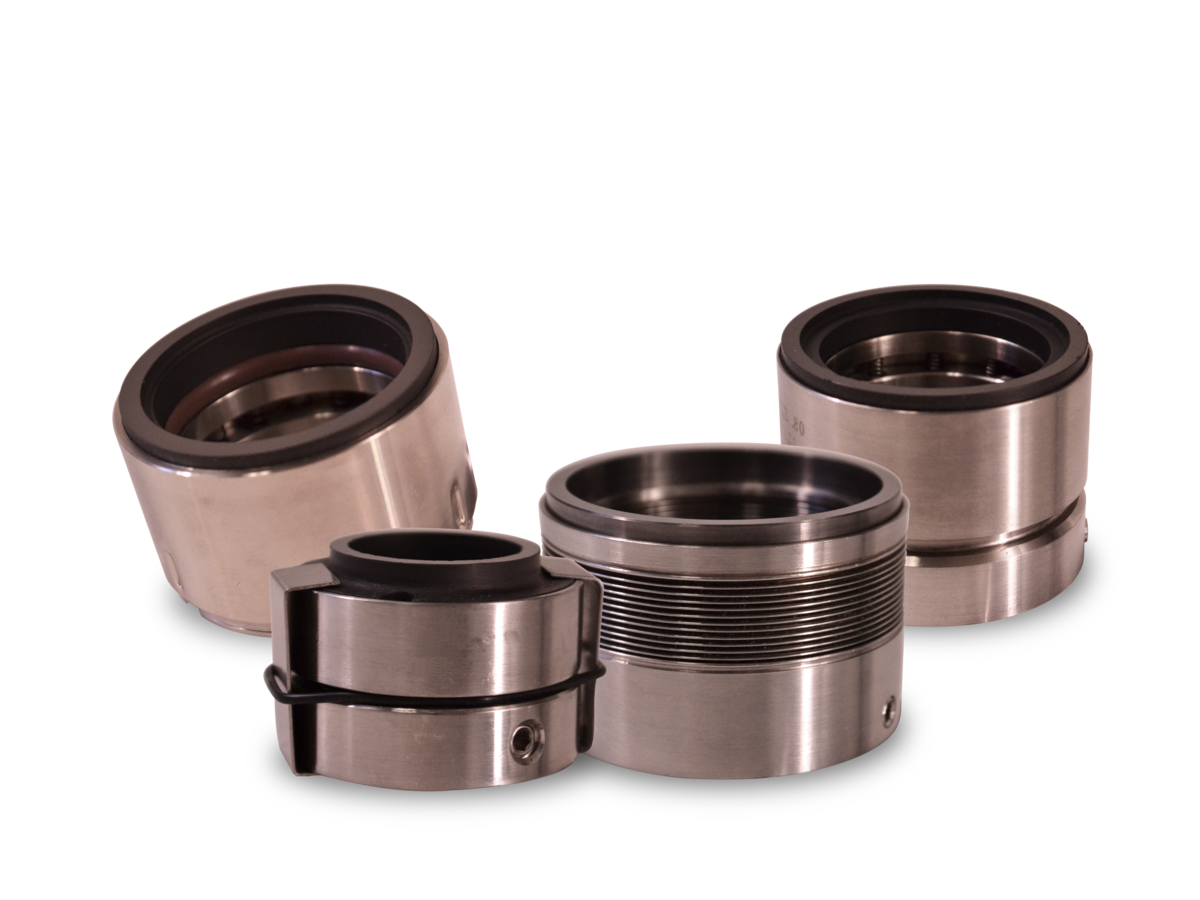

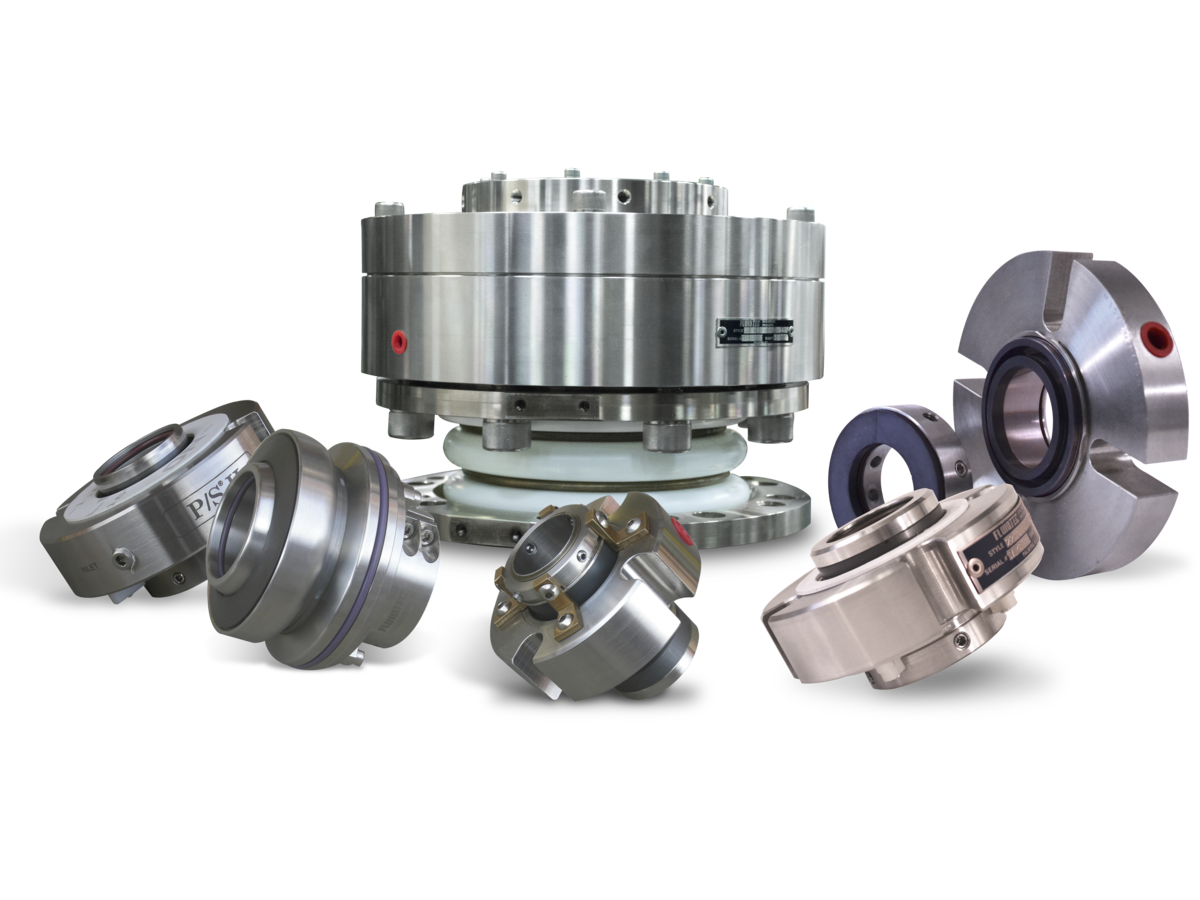

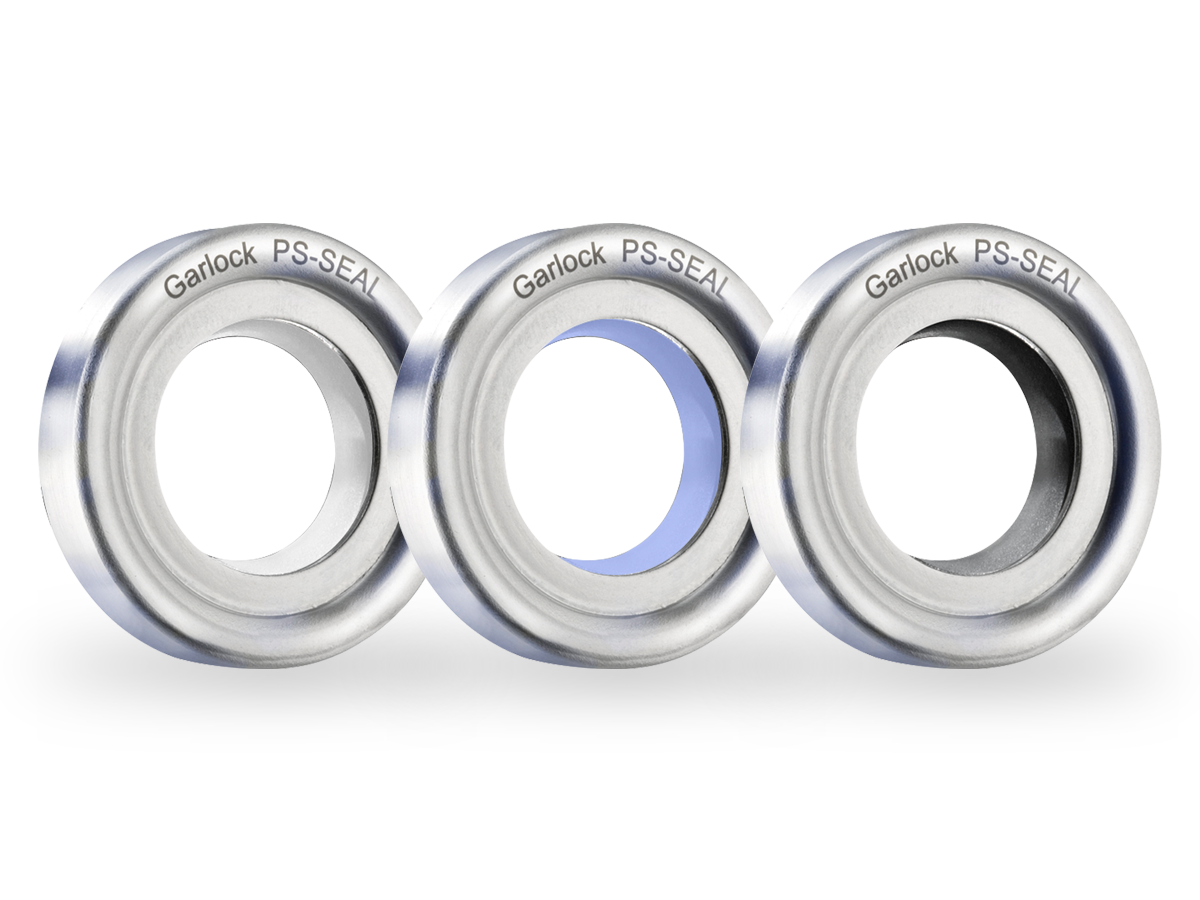

KLOZURE® Mechanical seals for pumps, agitators mixers and other rotating shaft applications are available in both lip and face seal designs in four primary styles and a wide range of sizes. Key products include P/S®-II lip seal, Syntron RP shaft seal, PK component seal, and the GMP series of single and double cartridge seals.

We manufacture mechanical seal solutions for numerous applications in the chemical, pulp and paper, mining, and power generation industries.

Component Seals

Separate rotaries and stationaries for inside and outside mount applications.

Cartridge Seals

All-in-one seals that provide simple sealing solutions and ease of installation.

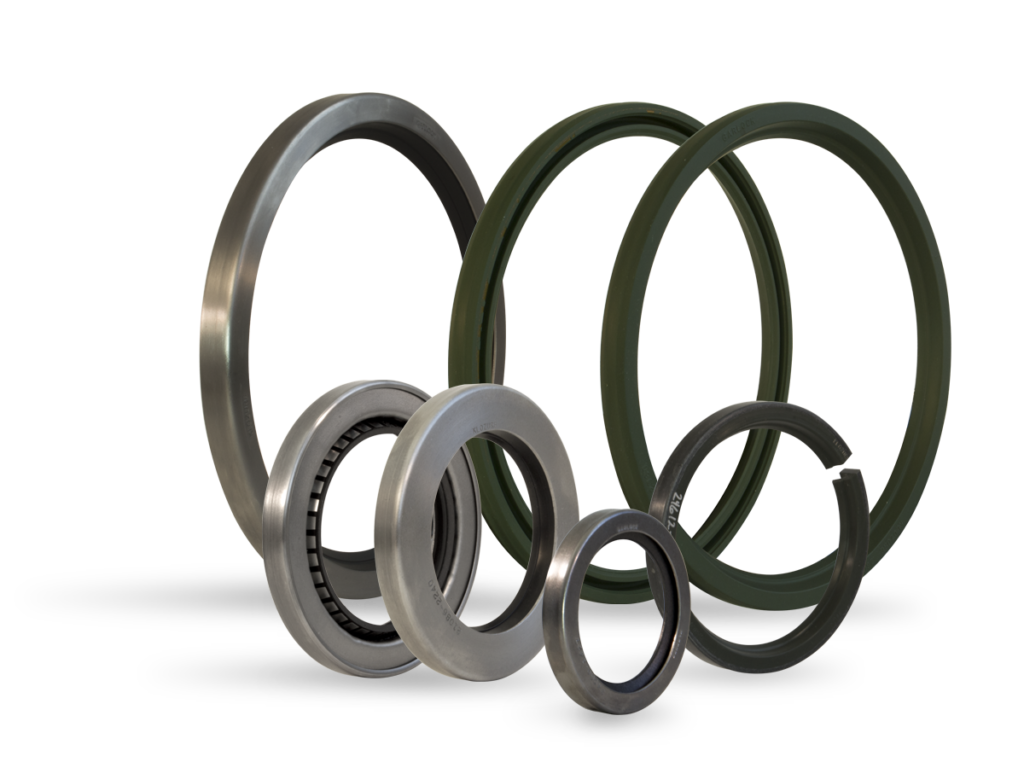

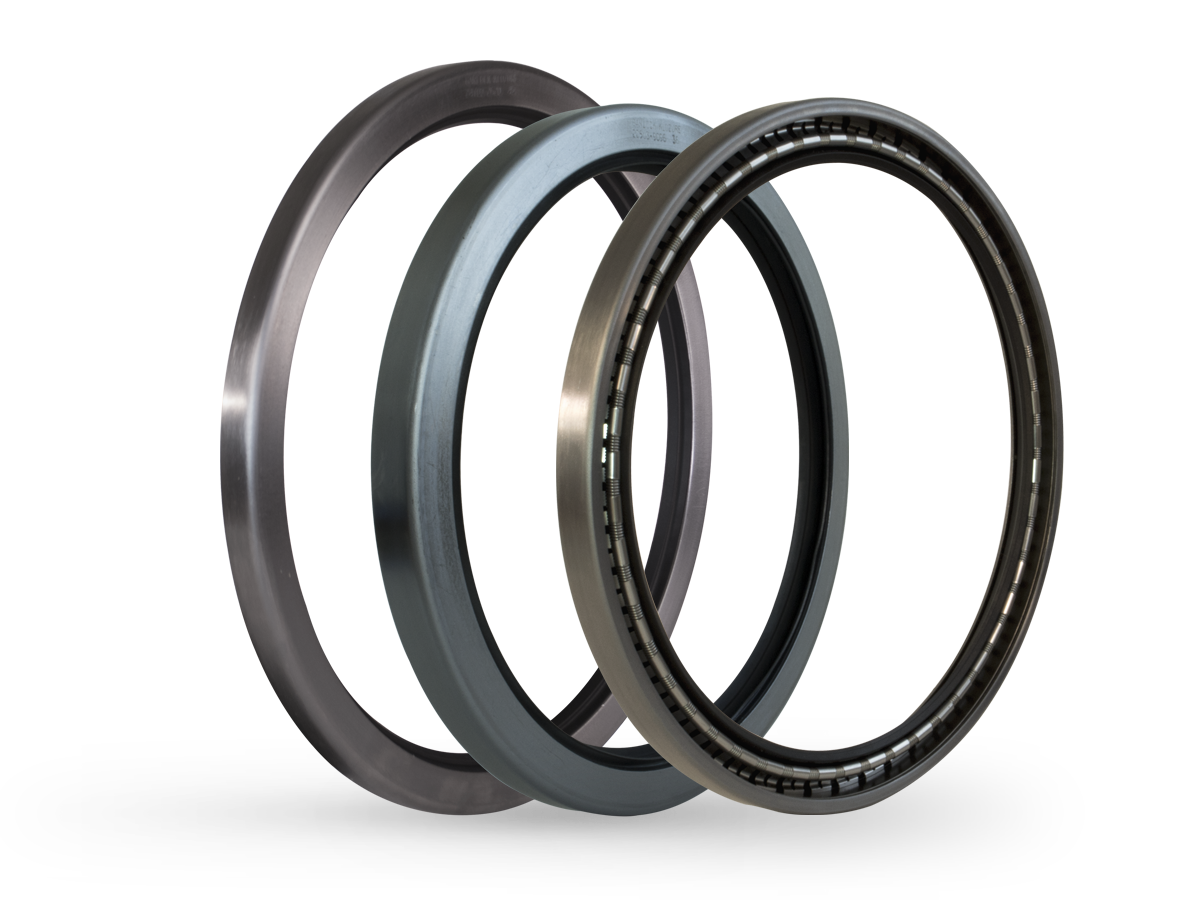

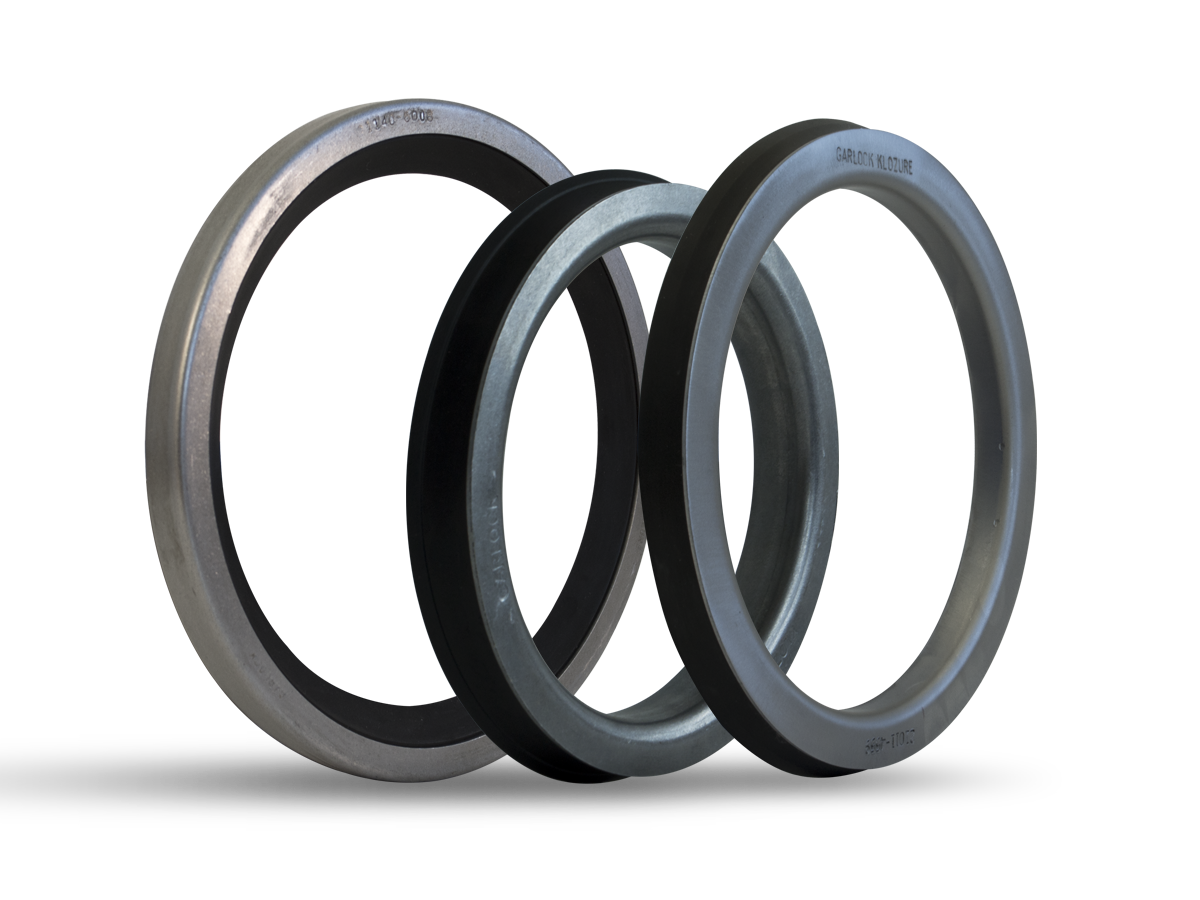

KLOZURE® Oil seals from Garlock® KLOZURE® are available in a wide variety of configurations to meet the requirements of major industries. MILL-RIGHT® materials are used on all elastomeric seals for superior bearing protection. KLOZURE® Oil Seals are available in more than 50 different styles in sizes from ¼” to over 90″, solid or split, metal-cased or all-rubber. KLOZURE® Oil Seals have had a strong brand presence in the U.S. since the 1920’s. Today they are also manufactured and branded in China and Germany. Technology has advanced over the years, and the oil seals are now available in MILL-RIGHT® elastomers which provide longer service life than their predecessors.

Heavy Duty Seals

Heavy duty seals for steel mills, paper mills and mining applications

General Purpose Seals

Lip seals for pumps, motors, gearboxes and other general industry applications.

PTFE Shaft Seals

For applications with harsh chemicals, or food presence, PTFE shaft seals provide excellent wear properties and dry running characteristics

Specialty Seals

Special purpose oil seals are recommended for high-speed applications, reciprocating service, spherical bearings, tapered roller bearings and…

Excluder Seals

Excluder seals are designed to exclude contamination only, meaning they will not retain oil or grease lubrication.

LubriKup®

Fully molded cups and packing specifically designed for the oil production industry.

Downhole Sucker Rod Pump Seals

For downhole sucker rod pump applications

Garlock LubriKup® Sealing products including flange rings, split rings, and pressure actuated rings.

Polished Rod Stuffing Box Packing

Garlock’s foundation is build on our customers critical demands and the demands of the industries we serve. To this day , Garlock still customizes material formulations that make our products best in class. We take great pride in the engineering group that delivers these unique material formulations. With our strong history and knowledge base , Garlock is your partner to take your company to the next level.

Premium Rubber

Incompressible, extensible, highly impermeable, elastic. Available in rolls, yard-lengths, and cut gaskets

Reinforced Rubber

Combines elasticity and extensibility of rubber with the strength of a fabric insert.

Custom Molded Products

Engineered materials manufactured to your specifications

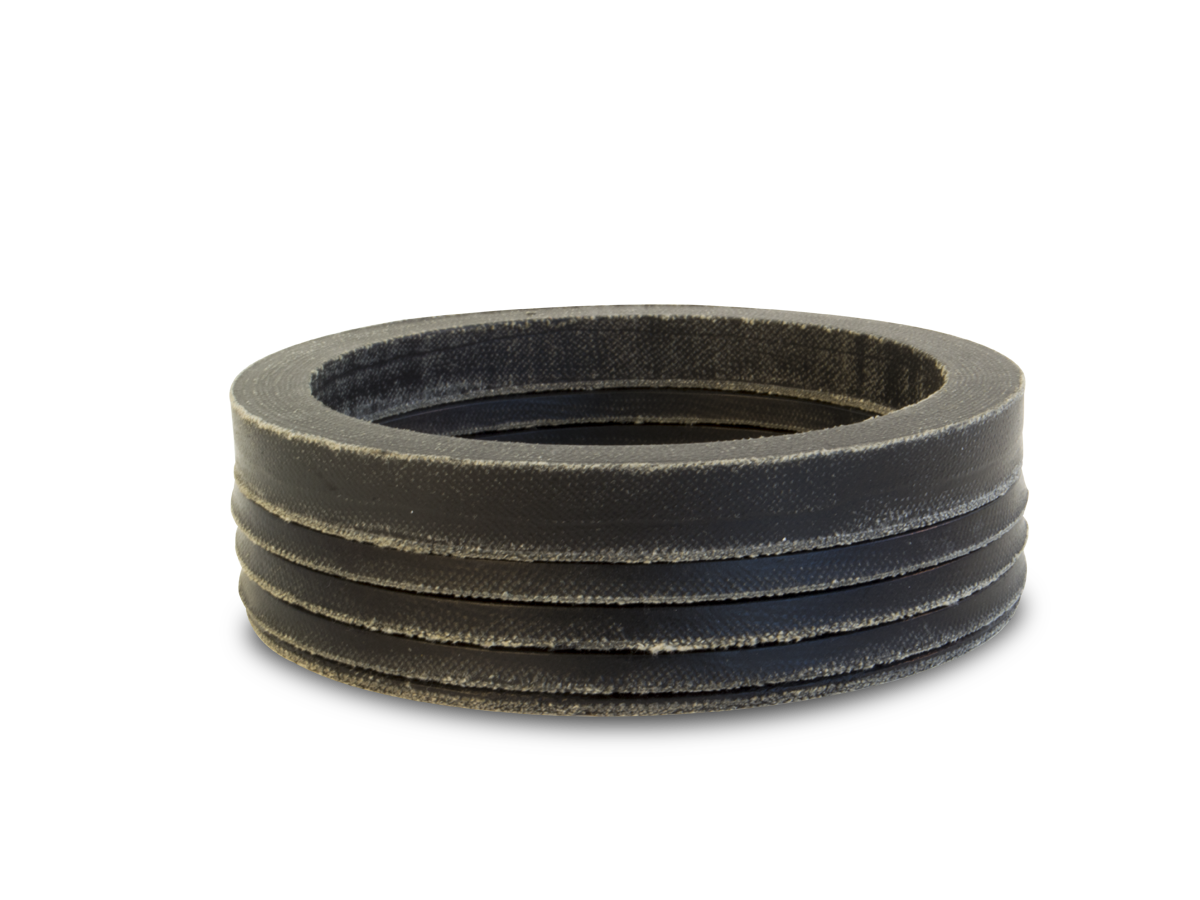

Fabric and Rubber Packing

Hydraulic Packing produced from slab stock

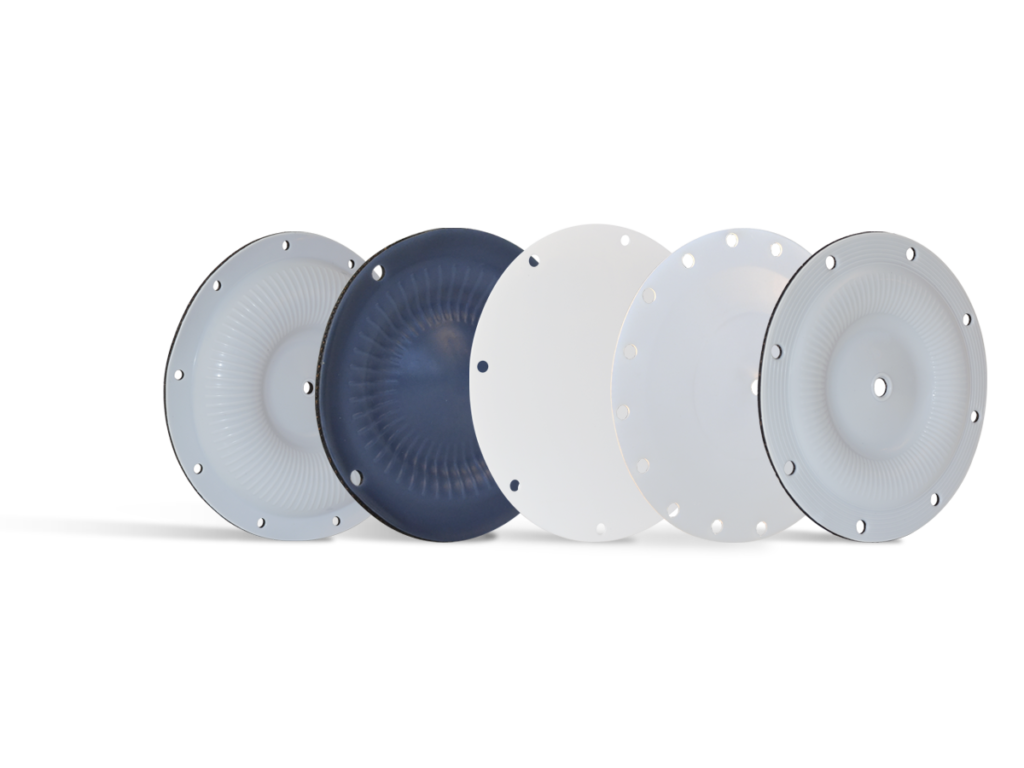

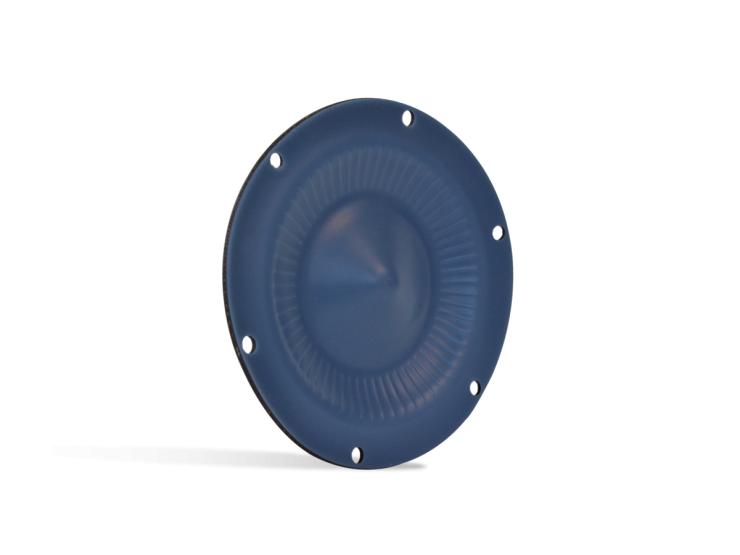

Garlock manufactures the most durable and long-lasting pump and valve diaphragms available, reducing equipment downtime and increasing productivity. From pure PTFE to one-piece bolt-on PTFE bonded rubber diaphragms, if you have a difficult or critical application, Garlock has the diaphragm to meet your needs.

Garlock ONE UP® Pump Diaphragm

Resistant to chemicals, abrasives, high temperature, and high pressure.

GYLON® ONE-UP® Pump Diaphragm

Optimal solution for sanitary applications in air operated diaphragm pumps.

GYLON® Style 3522 Diaphragm Material

100% PTFE diaphragm offering the longest service life in the industry.

Style 7992 Neoprene Diaphragm

Neoprene rubber diaphragm with hose duck fabric insert.

Style 8798 Neoprene Diaphragm

Neoprene rubber diaphragm with nylon fabric insert.

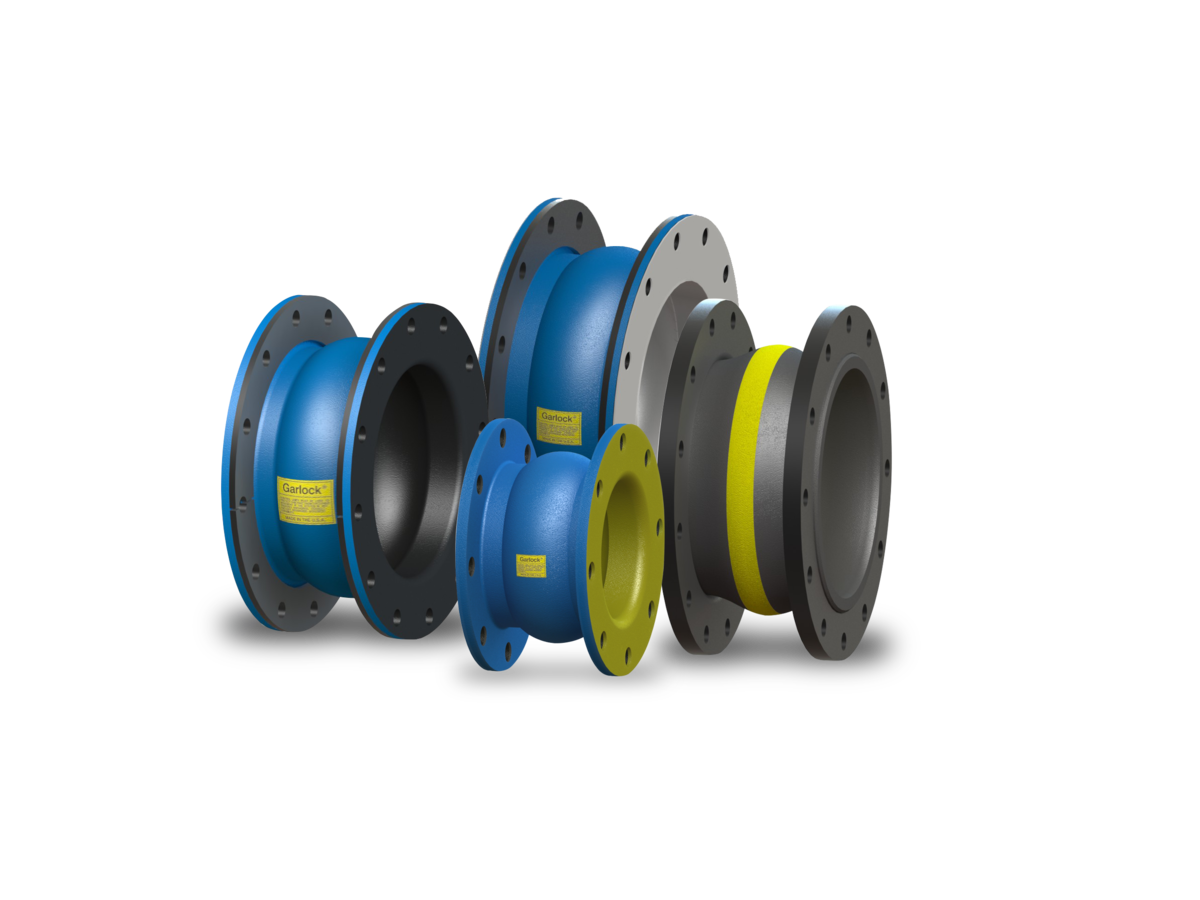

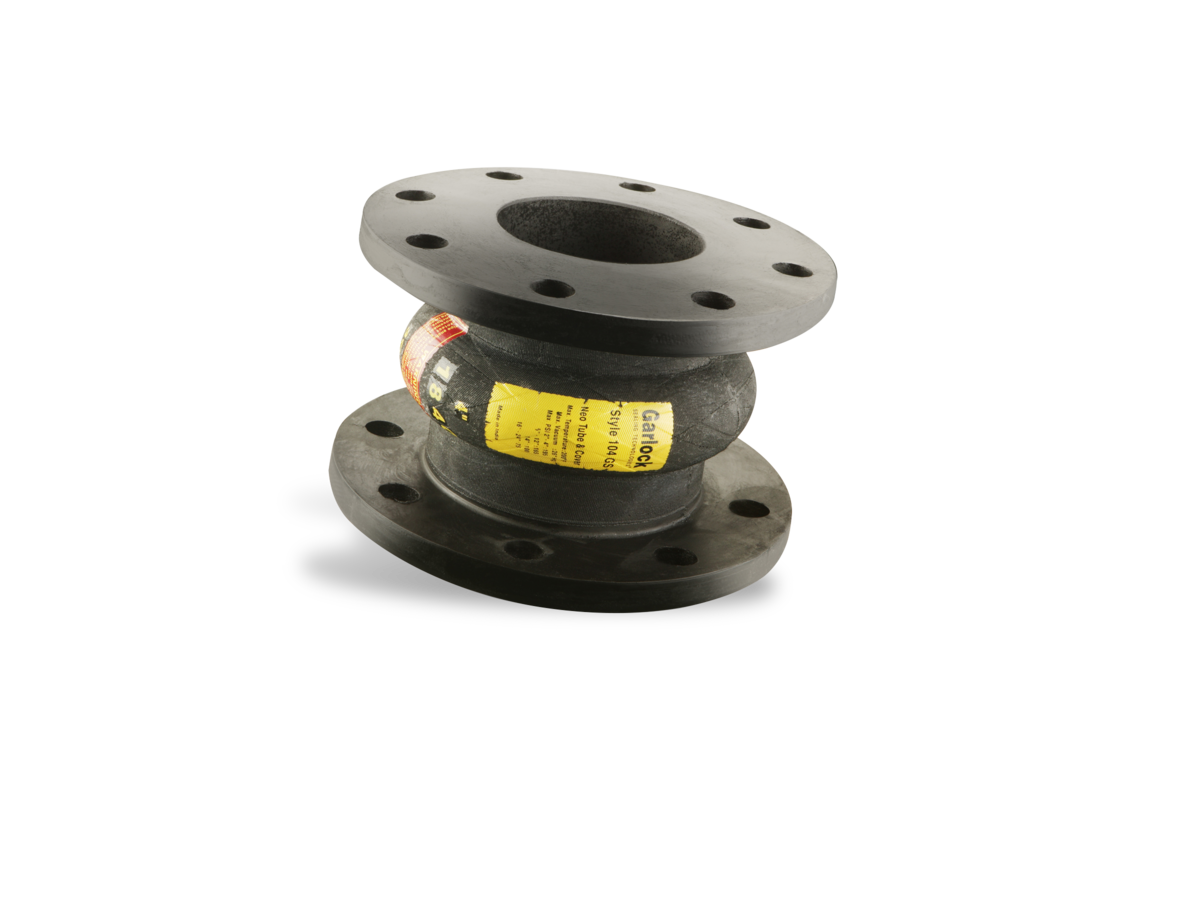

Garlock Expansion Joints offer superior performance, reliability, and service life, resulting in improved plant safety and increased mechanical integrity of equipment. As specifically engineered products that are inserted in a rigid piping system, Garlock Rubber Expansion Joints will:

Absorb movement

Improve thermal stability

Relieve system strain due to thermal change, load stress, pumping surges, wear of settling

Reduce mechanical noise

Compensate for misalignment

Eliminate electrolysis between dissimilar metals

All of our expansion joints carry safety ratings that exceed product specifications in areas such as pressure and movement. Non-metallic expansion joints and flexible couplings are ideally suited for a wide variety of industries.

Piping Expansion Joints

Expansion joints designed for piping systems.

Ducting & Low Pressure Expansion Joints

For ducting, low pressure, or gravity fed applications..

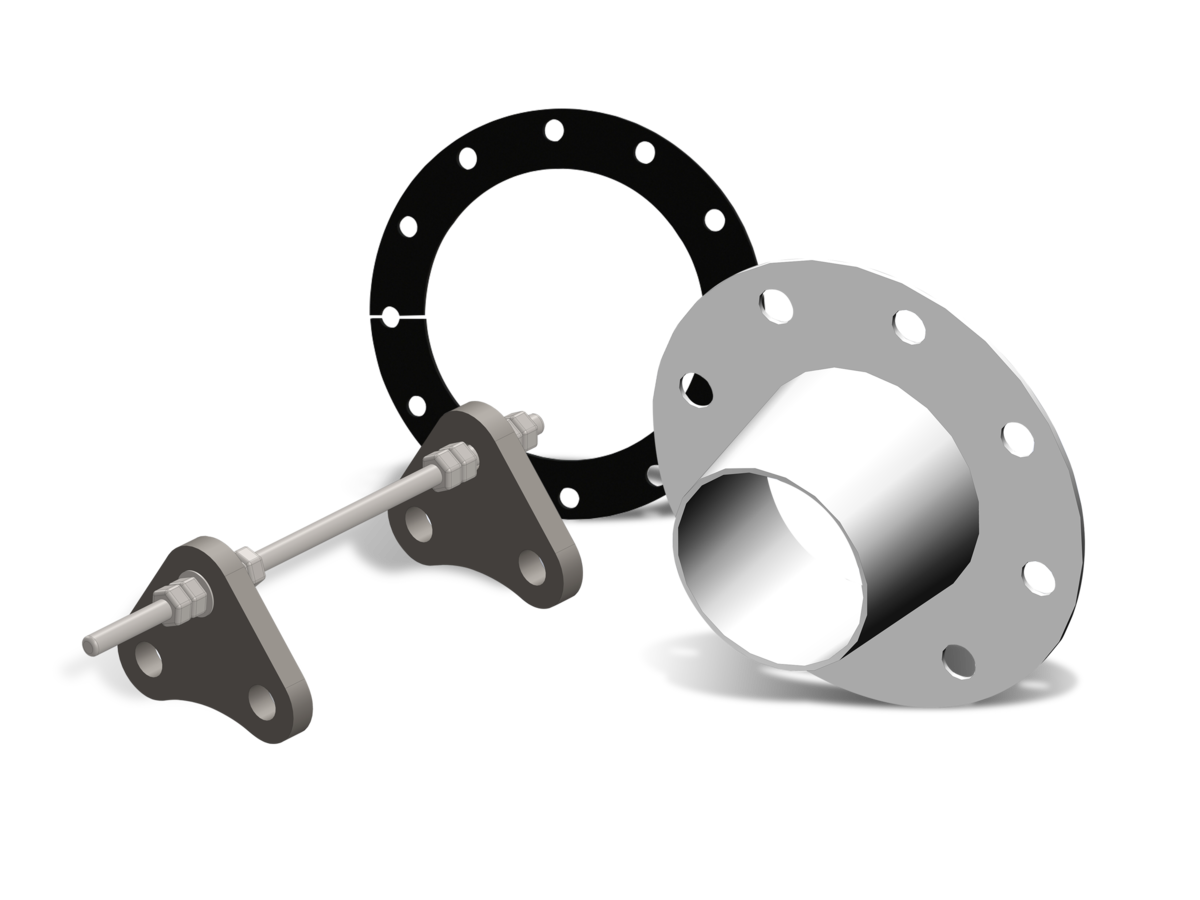

Common Accessories for Expansion Joints

Common accessories for Garlock rubber expansion joints.

Discontinued Rubber Expansion Joints

These products are discontinued and no longer available.

Garlock

Promoting Safety Through Quality Products

The Garlock family of companies is committed to promoting a worldwide culture of safety, as it is the most important part of who we are. Our newest safety video showcases the value behind using thoroughly tested and carefully engineered products to keep your workers safe.

Garlock Global Presence

Garlock is committed to safety and quality all over the world. With locations throughout the globe, we’re always close to you.